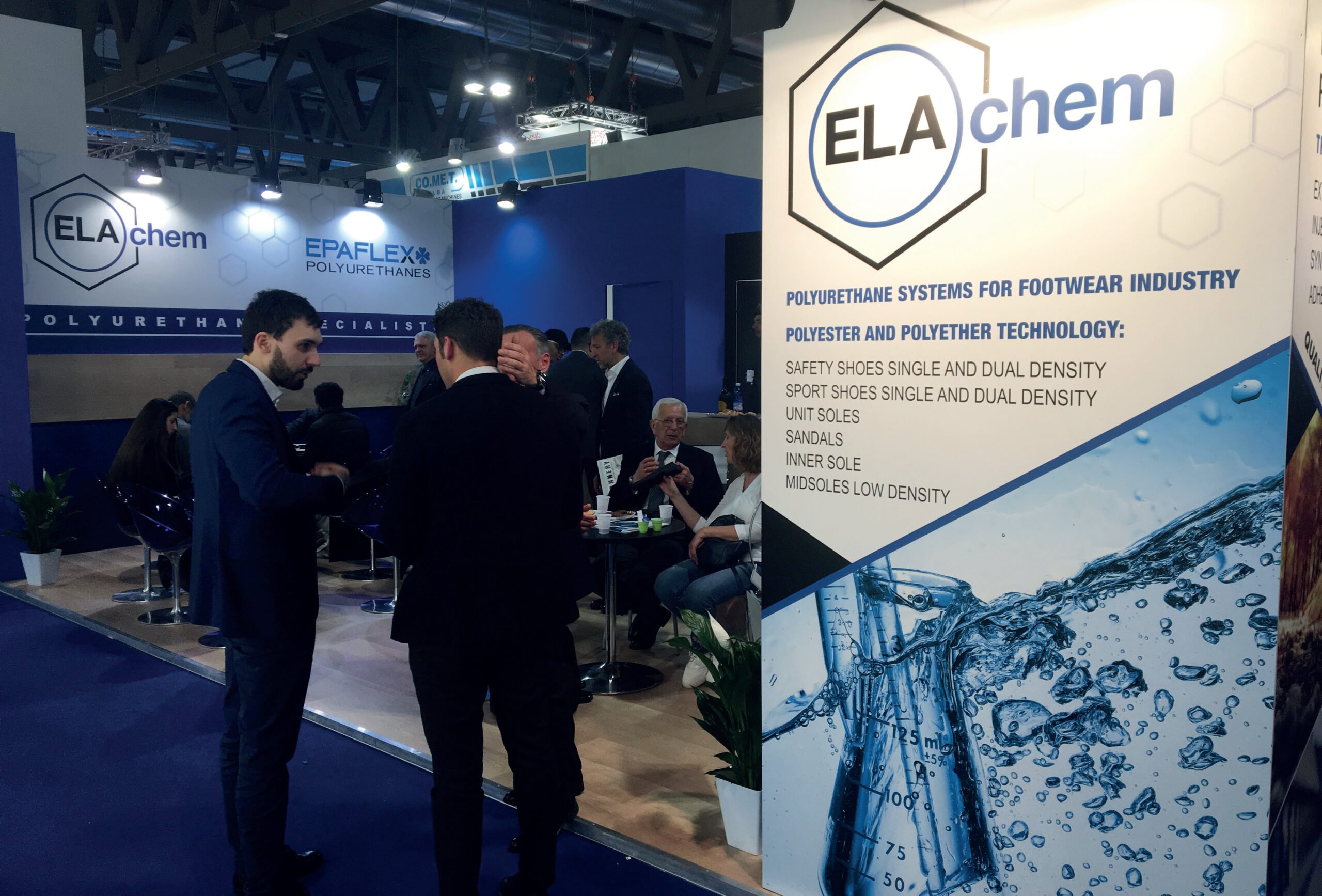

Established in Vigevano in 2001, Elachem SpA is specialized in the production of polyurethane systems to be used in several end sectors, including the footwear industry. Over the years, the company has chosen to integrate a plant for the manufacturing of saturated polyester resins, designed according to the specific needs, relying on the firm’s well-established know-how.

Virginio Tatti e Federico Brusa

“Our history has allowed us to become a market leader, boasting an annual production amounting to 50,000 tons and satisfied business partners all over the world,” explained Federico Brusa, at the helm of the enterprise featuring over 100 employees. “Elachem’s flagships are its cutting-edge laboratories, thanks to which we can monitor the whole manufacturing process, from the design phase to tests.” The production processes are based in Italy, while the distribution network runs on a global scale.

What is the role played by technological innovation in your industrial policy?

“At the core of our fast and effective operation, there is technological innovation. Our laboratories are designed and built to ensure top-notch quality standards as far as production is concerned. Said facilities allow us to pay close attention to the whole manufacturing cycle, from the design up to tests and try-outs. The in-depth understanding of the sector, acquired over the years, has helped us implement a cutting-edge structure. In addition to that, through constant monitoring, we guarantee first-rate quality right from the beginning, from the development of each single molecule, in constant synergy with the customer’s demands, up to the tests carried out on the finished materials.”

Can you tell us something more about your range of products?

“Our products are employed in different end sectors. Ranging from the footwear industry, supplied with the Elapol polyurethane systems, the latter tailored on every type of needs and optimized to be used on all machines, up to the insulation field, featuring saturated polyesters mainly used for the production of insulating panels for several industrial sectors.Worth mentioning also the polyesters used for the production of adhesives for the footwear and flexible packaging sectors, the flexible foams conceived either for the automotive industry, as a key component both from a functional perspective and in terms of equipment, or for the making of synthetic leather. Last but not least, there are thermoplastic polyurethanes used for a wide selection of everyday objects such, for example, transmission belts, conveyor belts, ski boots, skates and carts’ wheels.”

What are the market demands?

“Customers are on the lookout for a product in lightweight, soft polyurethane,” explained Virginio Tatti. “Furthermore, in order to meet the growing market demands, we have recently expanded our plant, in order to increase the amount of polyester produced, both used in-house and sold on the market. Our main end sector is the footwear industry, yet there are others. Our industrial facility is currently one of Europe’s most advanced plants, and we are focusing more and more on polyurethane, since we strongly believe in this course of action.”

Elachem is also committed to the safeguard of the territory, thanks to sponsorship initiatives.

“We are the main sponsor of the Nuova Pallacanestro Vigevano 1955, the result of the partnership between Nuovo Basket Vigevano, Cat Vigevano and local supporters. The team nurtures also a pool of young talents and it is currently playing in the B League. We are truly satisfied.” www.elachem.com