Mirco Roncolato, Nexus

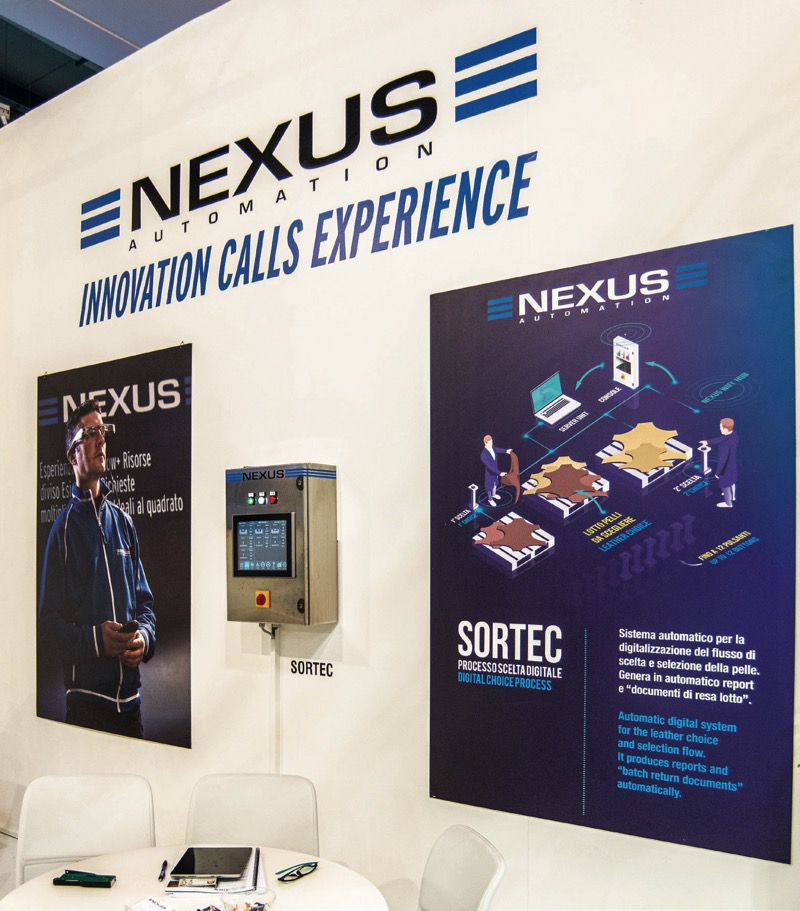

At the 2020 edition of Simac Tanning Tech, Nexus showcased the whole range featuring two new, cutting-edge systems, that is, SORTEC and MILLINGTEC.

The innovations developed by NEXUS on display at Simac Tanning Tech. At the latest edition of the fair, held in February in Milan, the company headquartered in Montorso Vicentino – a town based in the Arzignano’s tanning cluster (Vicenza province) – exhibited its whole range of products, able to gain a strong foothold both domestically and in the global market. Furthermore, the firm showcased two new automation models: on the one hand, SORTEC guarantees digital assistance to the leather selection process, while, on the other, MILLINGTEC provides the automatic management of milling drums.

Established in 1998, NEXUS can rely on a staff of qualified technicians with plenty of experience in the automation sector: currently, there are 22 employees, a number set to increase in the years to come, thanks also to the penetration in new markets. The enterprise deals with the design and manufacturing of electrical and electronic equipment for the automation of plants and machines to be used mainly in the tanning industry, but also in other business fields, in full compliance with the Industry 4.0 standards. The Veneto-based firm boasts a high-profile technical staff, whose well-established research skills, acquired over the years and aimed at the utmost customers satisfaction, have resulted in a professional, renowned service. The Saia-Burgess system integrator, provided from 2005 to 2013, has borne witness to the technical expertise nurtured and shown through time, then further upgraded in the last decade with other innovations. With these credentials, NEXUS has grown into a reliable partner for the production of plants and machinery for the industrial world, putting at the clientele’s disposal its know-how in order to find bespoke solutions for each single need.

“For us, the concept of Industry 4.0,” explained Mirco Roncolato, NEXUS’ co-owner and area manager, “is not merely a long-standing strategic choice, but also a work method and a production philosophy. Our core values lie in innovation, automation and interconnection; moreover, we can provide a comprehensive service when it comes to design, manufacturing, assembly, start- up and post-sale assistance. The well-established expertise of the corporate staff, always on the lookout for cutting-edge solutions, has helped the firm provide a widely praised, highly qualified technical service.”

“We can rely on more than two decades of experience in the business,” stated NEXUS’ co- owner, “and, during said years, we have become a trustworthy partner for the making of plants and machinery, by providing targeted technologies both on a local scale and to foreign firms, a trend confirmed by our steady growth internationally. Our reference sector keeps evolving and, for this reason, we carry on with R&D investments so as to give our customers, current as well as future ones, cutting-edge automation systems and machinery upgrades, all met with great success and now fully integrated in our range of products.”

Let’s take closer look at the innovations on display at Tanning Tech, starting with SORTEC. “It is a digital automatic system,” explained Roncolato, “conceived for the leather selection process. With this modern equipment, the traditional mechanical counting devices can be replaced by Wi-Fi buttons, the latter installed in a specific battery-less column: once pushed, they send signals to a PLC, that is, a “Programmable Logic Controller, that provides useful Reports and Database for the traceability of the selection process. In this way, the current manual handling of hides is upgraded effectively. Among SORTEC’s distinctive features, there are the identification via password of the employees in charge of the operation, the acoustic signal when pushing the buttons, the complete elimination of human error in case said buttons are pressed repeatedly. The plant is equipped with two to twelve buttons, according to the required stations, a choice that can be made even subsequently, as well as with the chance to interact with the corporate management system.”

“As far as MILLINGTEC is concerned,” added the co-owner of the firm based in Montorso Vicentino, “we can say that this automatic management system is the result of the need to automate milling drums, featuring either the old electromechanical system or non-upgradable electronical parts. Via the revamping of the old drums, namely, a substitution of the switchboard, the system can fall into step with the standards set by the current market. Here are some of the system’s core features: electrical equipment assembled and wired up in brushed stainless steel carpentry, a 12-inch HMI colour PC panel, Cartesian diagrams concerning the machine’s temperature and humidity levels, both the real and the set ones, as well as graphic representation of the drum’s rotation cycles, with the chance to focus on details. Worth mentioning also the fact that the automatic management is user-friendly and swift and it can be used in a manual, semi-automatic and recipe way, besides being able to send information via email or telegram (data messaging) when it comes to processing end and alarms.”