Serafini aims at the future by providing innovative product solutions designed to improve efficiency and safeguard the environment.

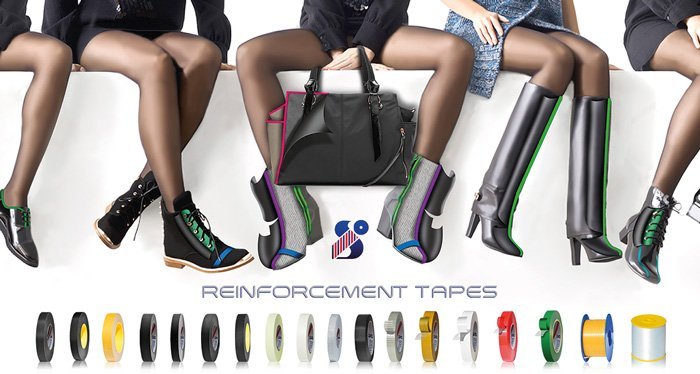

Adhesive reinforcement tapes, ant tapes, interlinings, synthetic linings, non-woven fabrics and micro-fibres. Featuring eight affiliated companies as well as three production sites based in Italy, Mexico and Portugal, Serafini Group, headquartered in Civitanova Marche, is now acknowledged as a leading enterprise in the distribution, in over fifty countries worldwide, of materials for the footwear, leatherware and leather garments sectors.

Marco Serafini

Dedication, hard work, experience and professionalism: these are the values lying at the core of the firm led by Marco Serafini, entrepreneur and ship owner with a strong passion for sailing. “I was forced to take up the reins of the family business when I was just twenty,” he stated, “because, at the time, my father had already turned 72. Since then, we have kicked off a significant internationalization process, by establishing strategic alliances, by investing in coating technologies as well as in product research and innovation, while paying close attention to collaboration and service efficiency.”

Today, Serafini provides sustainability-oriented solutions able to improve the quality of the end product, ensuring prompt, bespoke responses, tailored on each single production demand. Amidst the wide range of articles showcased at the latest edition of Lineapelle, a special mention goes to WaxCoat, that is, an exclusive finishing process developed by the company and suitable for several supports, yet able to especially enhance the functionality of microfibres. “Said treatment, successfully employed by the new Omac technologies,” explained Serafini, “reduces the hydrophilicity rate of the microfibre, namely, the absorbing capacity during the gluing phase, thus safeguarding its softness. Acting as a barrier primer, WaxCoat allows to use a smaller amount of adhesive while ensuring the same yield, resulting in top-notch adherence standards even when the glue is applied on a single side. Last but not least, it facilitates fleshing operations: WaxCoat helps maintain the dimensionality of the shape, thus avoiding any stretching or shrinking effect, the latter a very frequent occurrence in case of processes using this type of supports. A significant issue especially for the leatherware industry, that requires very low dimensional tolerances.”

The other interesting innovation is called Agavina. “It’s a non-woven fabric,” explained Serafini, “entirely derived from agave organic fibres, officinal herb used, among other things, for the distillation of tequila. Since it is a non-intensive cultivation, agave is not modified genetically. We use just the waste parts: a project revolving around the recycling and re-use of recovered raw materials that perfectly embodies the corporate commitment to sustainability and to the growth of circular economy. The ultimate goal is to replace the whole production of polyester fibres with those derived from organic waste.”

www.serafini.it