Apparel, footwear, industry. Rifra Nastri provides all market segments internationally with a product designed to meet every sort of style as well as technical and quality requirements.

Footwear is the sector that better embodies Rifra Nastri’s successful combination between products’ quality and creativity, materials innovation and targeted services. The elastic ribbons provided by the firm headquartered in Concorezzo (Monza-Brianza province) manage to meet the demands and requirements of the footwear industry and of other sectors, resulting in an ample selection of articles ranging from solutions with markedly technical features – conceived, for example, for the safety footwear field – to more fashionable items, purposefully developed in partnership with the most prominent brands’ designers and patternmakers. Rifra Nastri’s steady commitment to quality, both product- and servicewise, was in the spotlight even during the latest months, deeply affected by the Covid-19 pandemic. Roberto Riva, the enterprise’s owner, explained in detail the goals achieved and the initiatives to shape the future.

Roberto Riva, how deeply was your company affected by the complications arisen from the lockdown? Business never stopped fully. Given the fact that we produce, among other things, elastic ribbons for PPEs and workwear, we managed to get the authorization from the prefect. However, even though the firm kept on carrying on research projects and maintained a proactive attitude, work proceeded differently and more slowly: orders for the following season were sent a month late, and then we were striving to understand what would happen. Despite everything, at the end of the year, our turnover was only slightly lower compared to the 2019 revenues. If, on the one hand, some enterprises registered a turnover drop up to 80%, on the other, there are firms that experienced a growth in proceeds. Some of our customers were already equipped for e-commerce and turned the situation to their advantage: consequently, our order volume even increased. Instead, other shoe factories with whom we worked – based in the Marche region, in Tuscany, small-sized, less organized companies – were forced to close down in September. Let’s wait and see what happens this year, when the moment comes to get back on track without wages guarantee funds, subsidies, loans.

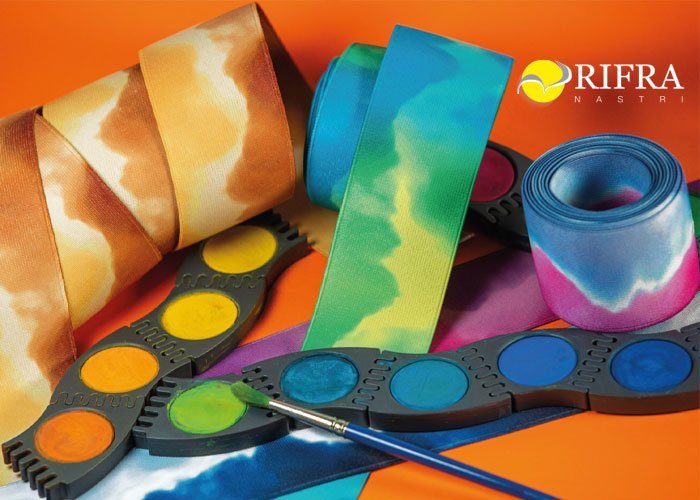

Style-wise, what are the new trends for ribbons? Our fashion articles for the 2021-2022 Fall/Winter season have put in the limelight warm effects, met with considerable success; on the other hand, we are a little late with the sampling of the 2022 Spring/Summer collection due to either the cancellation or the postponement of the key trade shows that we usually attend such as Première Vision Paris, Milano Unica, Lineapelle. Our strength lies in the ability to meet every demand with an ample range of solutions available in different models when it comes to processing techniques, materials, sizes, colours, technical features and customization level.

What can you tell us about the firm’s commitment to sustainability? The close attention to natural and green elements is more than a mere trend, it is an actual need, fostered by the most prominent fashion brands’ political decisions. Environmental awareness is higher, especially abroad. Brands are growing more and more interested in recycled as well as in organically grown yarns: our enterprise has been meeting this demand in the last few seasons with the Eco Rifra collection, that is, a range of fully natural products that embody the desire to look for new, environmentally friendly materials to be used in the manufacturing process, the latter upgraded as well sustainability-wise. Recently, we have signed a deal with a British company to get a large batch of elastic ribbons in organic cotton, the eco-friendly alternative to traditional cotton.

As for your products, how important are intrinsic quality and durability? We should focus on two aspects. Our products, whether elastic ribbons with markedly technical properties or more fashionable items, meet all the footwear industry’s requirements. As for the former, they are designed to guarantee over time the compliance with specific technical and quality standards. It is the most complicated issue, yet, in this way, customers are not forced to test the ribbon before its addition to the shoe’s manufacturing process. On the other hand, fashionable items are conceived to last one season: therefore, in this case, we aim at promptly fulfilling the demands of designers and customers. The elastic ribbons for the footwear sector are subject to strains and stress tests that are, by far, higher compared to the past, when they were used in a standard way. For this reason, they must feature significant intrinsic properties.

What about service? Each ribbon has its function. Therefore, the customer must understand the pivotal importance of such a reliable support service. A trust built over time, thanks to a well-established expertise and to long-standing experience. Putting oneself on the line, always.

What are your future prospects? In spite of such a negative period for the economy, we are thinking about expanding our premises. The project is taking shape: the addition of further 2,500/3,000 square meters, connected to the current facility, whose surface amounts to 4,000 sqm., so as to optimize the spaces dedicated to offices, to the production, department, to the warehouse and to the logistics division. It may seem reckless, but I believe that entrepreneurs should always seize new opportunities to either improve or increase their business. Incentives are necessary to carry on. Therefore, fingers crossed and let’s tackle this new challenge.

www.rifranastri.it