Gemata presents the sustainable finishing line Multi Greenfinish

The challenges of the 21st century for the tanning sector are increasingly ambitious: constant technological innovation, significant reduction of environmental impact and a strong commitment to high-quality standards are now essential. Growing awareness of the importance of sustainable development has sparked a transformation in the industry, led by companies dedicated to both progress and environmental responsibility. Among these pioneers, Gemata stands out as a global leader in designing leather finishing systems. For years, Gemata has pursued a vision of sustainability, summarized in its motto: “Less waste, more nature.”

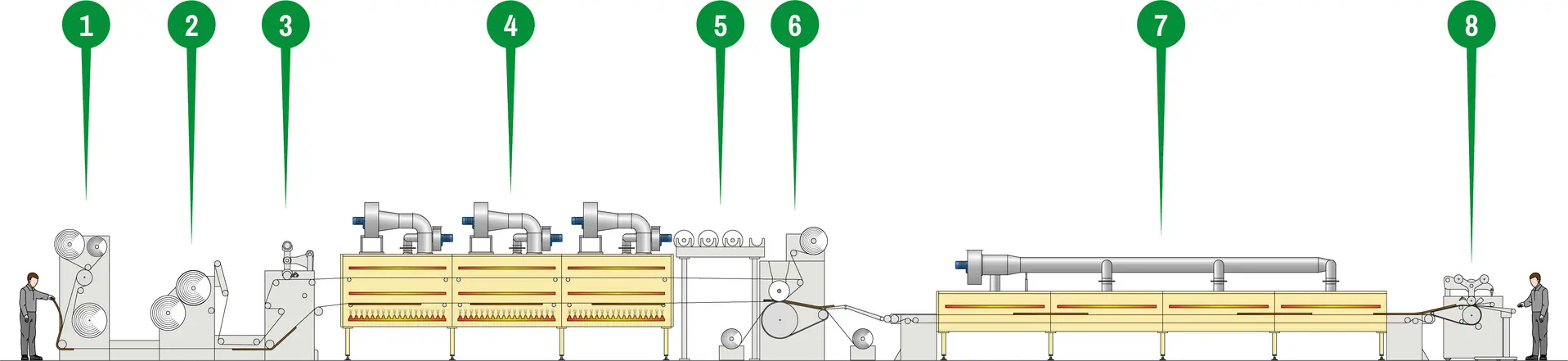

Multi Greenfinish, the company’s latest innovation, is a groundbreaking finishing line that utilizes both release paper and embossing rollers to process hides up to 2500 mm wide, achieving a greater variety of grains, including larger grains than those typically achieved with traditional methods. Building on Gemata’s extensive experience with over 50 Greenfinish systems installed worldwide, Multi Greenfinish combines versatility, efficiency and sustainability, redefining the standards of leather finishing.

This versatile system employs two distinct technologies to meet diverse finishing needs. It utilizes release paper for the upgrading of ovine, half bovine, and calf leathers, destined for leather goods and footwear, creating exquisite satin, nubuck or fine-grained finishes. Alternatively, it employs chromed steel embossing rollers, protected by a thin plastic film, to produce thicker grains, such as saffiano and dollar. This innovative solution allows for the finishing of large-sized hides, such as whole calf hides. Both configurations deliver a uniform, high-quality finish, free from surface defects, preserving the leather’s natural softness.

A further advantage offered by the system is the gain in footage, which can vary from 1.5% to 2.5% more than traditional finishing. This improvement is achieved through the firm adhesion of the leather to the release paper or protective film during the low-temperature drying process, which prevents shrinkage.

Like its predecessor, the Greenfinish line, Multi Greenfinish minimizes environmental impact and energy consumption by utilizing roller machines instead of sprays. Furthermore, the spent film is a recyclable resource. Thanks to its versatility, this line can be used not only for finishing leather but also for processing regenerated leather and other synthetic materials in rolls, which are increasingly in demand. This contributes to a circular economy and reduces waste.

- DETACHING CONVEYOR TABLE; RELEASE PAPER CLEANING UNIT AND PAPER/PROTECTIVE FILM REWINDER; RELEASE PAPER OR PROTECTIVE FILM REWINDER

- TWO-STATION FIXED UNWINDER; JOINING TABLE UNIT

- GREENLINE 2R ROLLER COATING HEAD

- DOUBLE STARDRIER-IR INFRARED DRYING TUNNEL

- EMBOSSING CYLINDER STORAGE

- ROTARY MULTIPRESS

- STARDRIER-IR INFRARED DRYING TUNNEL

- GREENSTARs ROLLER COATING MACHINE