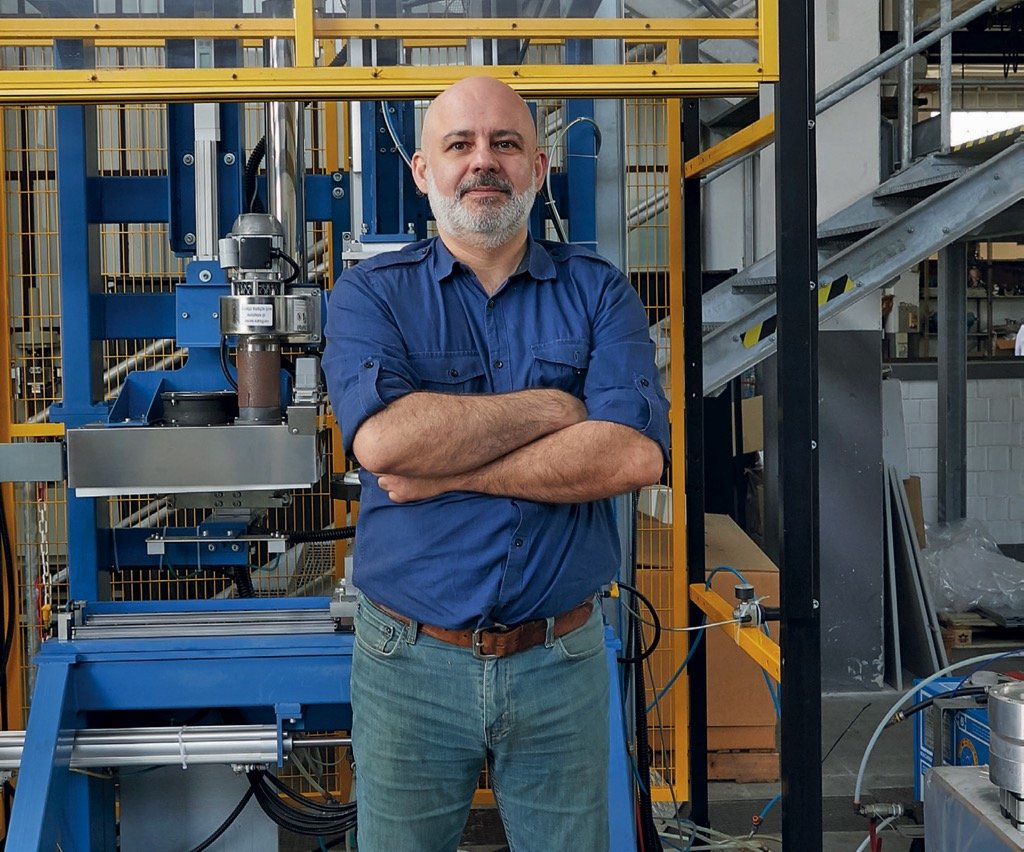

Open to global markets, the polyurethane molding machine manufacturer provides turnkey systems for 50 percent for the footwear industry and the remaining 50 percent for other types of products. Upgrading and sustainability are their keywords

Gusberti and Bianchi. Two surnames merged in 1946, at the dawn of the Republic, to give birth to a new entrepreneurial story signed Gus-Bi, a manufacturer of polyurethane molding machines and systems led today by the third generation of the Bianchi family: Irene, a graduate in Economics and Commerce, has been with the company for twelve years and she’s Sales Department manager as well as Assomac advisor. Matteo, on the other hand, a graduate in mechanical engineering, has been with the Technical Department for three years.

Gusbi was created from the vision of two partners united by the same passion and experience in repairing and building footwear machinery, a so much important trade for Vigevano, a long- lived Italian and world capital of shoe manufacturing. “When the War ended,” Giancarlo Bianchi, eldest son of founder Terenzio and president of Gusbi for the past seven years, tells us, “there was a shortage of spare parts for machinery imported from the United States and Germany. My father and Emilio Gusberti decided to start their own business to meet the pressing needs of the footwear machinery industry in the district.” From here began the path of growth and innovation of a piece of Italian manufacturing.

The Vigevano-based plant extends over an area of five thousand covered square meters, divided into two warehouses. The first, original from 1963, houses the production department, laboratory, testing room, and assembly; on the first floor are the administrative, sales, purchasing, and after- sales offices, and management offices on the second floor. The other site is divided into twin parts, housing the technical department, machine tool workshop, a warehouse.

Gancarlo Bianchi, what is the history of your journey? Can you tell us any anecdotes?

“In 1939, at the age of 15, Terenzio Bianchi began his working career at a workshop specializing in the construction of machines for sewing soles, while at the same time attending night school at the Roncalli Technical Institute. Driven by the desire to start his own business, in 1946 he founded the Gusbi company with Emilio Gusberti, starting the production of the first Goodyear insole machinery. Later, he expanded his business by devoting himself to the manufacture of vulcanizing machines for rubber.

Also during that period, Terenzio Bianchi and Emilio Gusberti, a workshop technician, started the construction of the first rotary machines for molding PVC for the creation of sports shoes. Gusbi machinery as early as the 1950s reached Japan, China, Mexico, and Argentina.

His encounter with polyurethane, however, dates back to the late 1960s. One day a well-known entrepreneur, a sole manufacturer, showed up at the company with two containers of liquid: he needed a rotary machine that, by inserting the two components (polyol and isocyanate) inside a mold, would be able to produce a sole. Since the first tests started in Vienna, polyurethane had come to Italy for the first time! We built two polyurethane molding machines for him. A new ‘branch’ of the company had been created, but there was a lack of virgin raw material on the Italian market. Thanks to collaboration with the chemical industry we started the search for the formulation, proceeding in parallel with the PVC processing machines. However, these were beginning to be imported from China at very low prices, while polyurethane was now a coveted product. We decided to focus everything on the latter, addressing the different methods of the two molding systems, by casting and by injection. Since then, polyurethane has become the beating heart of Gusbi.”

When did the second Bianchi generation, consisting of ffiancarlo and Marco, join the company?

“Both with degrees inherent to mechanics, I as an engineer and my brother Marco as a specialist, we joined the company in 1980. In 1985 Emilio Gusberti decided to sell his 50 percent share to the Bianchi family, which then acquired 100 percent of the company. I was assigned to follow the commercial side, and my brother the technical side.

At the beginning of the 1990s, the footwear sector marked a significant slowdown, so we decided to expand our sphere of influence: Gusbi technology could find application in all product sectors that employ this type of material in the manufacture of their products. Participation in targeted trade fairs introduced us to the automotive and bicycle markets, for the production of gaskets and filters, and bicycle saddles, respectively. In this way we were able to achieve turnover targets split 50/50 between footwear and technical goods.”

Have you ever thought of taking part of your production abroad?

“Traveling a lot, we would have had the opportunity to build our machines abroad. However, the decision to manufacture in Italy has always prevailed, using, as our main suppliers for pneumatic and electronic components, the cooperation of major German companies such as Festo and Siemens, not because Italian companies were or are less reliable, but because the spare parts of these companies are distributed worldwide and service is direct.”

What added value does your after-sales service deliver over the competition?

“The company provides ‘just in time’ after-sales service operating in every part of the world. We have created over the years a network of Gusbi agents with assembly, service and spare parts warehouse activities where professional figures operate that are trained in Italy by our technicians and salaried by us. The Delhi office covers India, Bangladesh and Nepal, we have an office in Qingdao that follows China, Korea, Vietnam and Indonesia. Then again we have a presence in Brazil and the state of Maine to serve the U.S. and Mexico, a very important market from the aspect of automotive filters as well as safety footwear. We have an agent in Poland, one of the first European countries to produce footwear at volume and automotive equipped with infrastructure and skilled labor.

We always know the temperature of the situation because any service intervention, modification, any request for spare parts and offer of machines go through our headquarters in Vigevano. We use a single e-mail address that allows the entire staff simultaneously to have an overall view of business processes, and the staff directly involved in solving a problem to intervene in a synergistic and timely manner.”

Irene Bianchi, the continuous innovation of materials dedicated to fashion and safety often requires a design rethinking of production machinery. What role does research and development play at Gusbi?

“Working on a contract basis, our industrial polyurethane molding plants are configured to suit individual product requirements, productivity, budget, but also trivially the colour of the machinery and the space available to house them. This makes them open to continuous fine- tuning. Product and process innovation is the order of the day in our company, for each project we decide what more can and should be done to improve, step by step useful details and upgrading solutions are added in a continuous dialogue with clients and suppliers. Polyurethane itself is a material of great versatility that is always amenable to improvement, for example in terms of light weight and color retention upon exposure to ultraviolet rays.

In addition to implementing automation in accordance with the principles of Industry 4.0 for more than a decade, under the new ‘Transition 5.0’ plan, we are carrying out research projects on energy saving, with the ongoing goal of providing solutions that place consumption reduction at the center of the production process.

Our machinery requires expertise not only at the mechanical and electrical/electronic level, but also at the chemical level. In fact, it is the machine that adapts to the demands of the polyurethane and not vice versa. We set the machinery according to the data sheet provided by the chemical company chosen by the client, establishing a real synergy between machine and chemical product.”

Where are you with your sustainable development goals?

“As manufacturers of polyurethane molding machines, we try to form a system with those chemical companies of raw materials and additives for polyurethane production that apply sustainability criteria.

To improve the working environment, we are careful not to use harmful substances. For example, we use water instead of solvent for washing the mixing head. In recent years there has been growing interest in the production of recycled polyurethane soles. We are ready to provide a technologically advanced product in this regard, even in a 5.0 key, but at this time we do not see from clients a propensity to invest.”

What new products will you be presenting at Simac Tanning Tech at its 50th edition?

“We will be ready with a facility intended for a client in the saddle industry that we will supply already equipped with those energy recovery devices I mentioned earlier. We will focus on the processing of recycled polyurethane, hoping that the interest already shown by clients will turn into investment in machinery. We are a company in constant evolution: at Simac we will bring further improvements in software product performance, particularly for traceability.”

How is your collaboration with Autec Automation progressing?

“We are an established partner, almost sharing one heart with the Tuscan robotics company. Autec supplies the entire automation line studied and designed on our machines both in the footwear sector and in the automotive filter sector where we generally deal with multinationals from subsidiaries all over the world. In this way we are able to satisfy, with a state-of-the-art product of the highest quality, even that target market that needs complete automation. The machine for saddle production, for example, will be equipped with two robots for automatic spraying of a release agent on the mold surface. The adoption of automation, especially in the footwear industry, depends on the geographical segmentation of the market. However, 90 percent of our machines now adopt a robotic system – a must if the challenge is to be able to provide solutions capable of restoring productivity, efficiency, flexibility, waste reduction and therefore a competitive edge for our clients.”

What about machine rental services?

“We have three laboratory machines for sale that we can also rent out to start production while waiting for the new machinery to be delivered, or for a future investment related to a plant customized to client needs.”

What difficulties do you face in sourcing the professionals you need?

“Training young people in the required professions is a real emergency. While there is a crisis in the industry market, we are having a hard time finding a workforce willing to enter the factory, even in the face of opportunities for growth, travel, and higher-than-average salaries. Social media does not help us communicate our reality, there are no platforms related to mechanics and industry because the topic is not of interest. In addition, there is no secondary school that prepares, for example, software designers for PLCs, despite the fact that electronics nowadays is the basis of any technological device.”

From the left, Davide Spessa, Irene Bianchi, Matteo Bianchi, Alberto Buffonini and Emiliano Terreni

A bird’s eye view of the plant

The production department and Gusbi team

The recycled polyurethane processed by Gusbi machines

Laboratory, testing room and assembly room

Sales profiles with technical requirements

Emiliano Terreni has worked at Gusbi since 1994, Alberto Buffonini, husband of Irene, since 2016, the two technical sales figures who every day put their professionalism and passion available to clients, contributing to the success and growth of the company. Only through teamwork do we arrive at a winning solution.

Emiliano Terreni, tell us your story.

“Born in 1971, I was hired at Gusbi in 1994 after graduating from accounting school and doing my military service. Giancarlo is also a family friend; at the time the company was looking for a technician to join the workforce and I was a great mechanical enthusiast. I started at the foundation by assembling mold holders and then gradually moved on to the installation, testing and set-up stages of the entire range of Gusbi machinery. I followed the workshop with the grandfather of Irene and father of Giancarlo and Marco. Terenzio taught me everything about polyurethane. Today I’m still here and I’m in charge of both the commercial and technical side as lab manager, with a 360-degree experience. A plus aimed at understanding the challenges and needs of the client, giving support in after-sales and working alongside them in solving problems. The filter sector compared to footwear requires a more articulated and challenging approach, but also more stimulating.”

Alberto Buffonini, what is your background?

“I came to Gusbi eight years ago from the service sector, after working for several airlines and participating in the startup phase of the high-speed sector of NTV (Italo). Then, when Irene and I were not yet married, Giancarlo asked me if I would be willing to travel in his place to attend industry trade shows. I have a degree in languages, a prerequisite for a company that trades a lot with foreign countries. At the same time, I work for PU Tech, a company created by Gusbi and Autec to invest in the business sector.”

In your opinion, how has the commercial approach changed over the years?

“It has changed a lot from the old school, when the salesperson was always willing to say yes in order to sell. Being condescending and then going back on your word over time is counterproductive and does not indicate professionalism. Buyers today appreciate an honest and sincere human approach, they demand transparency not only about the achievable performance of the product, but also about delivery time. The difference is perceivable even in the clothing adopted, now preferably more casual, but recognizable. Jacket and tie often intimidate and make contact more difficult.

The competitors are many, Italian and otherwise, but we have broad shoulders, we are strong thanks to a great story of commitment and concrete values that deserves to be told and that involves all the actors, employees, managers and of course clients.”

Emiliano, how important is it for you to participate in trade shows?

“We believe in the trade show and participate in the different industry exhibitions, which is a great opportunity to increase visibility and get known by potential clients, but also an effective way to take care of the company identity. Participating in Simac, although it is an event dedicated to the footwear machinery sector, we still have the opportunity to engage other sectors related to polyurethane. Especially when one is still unfamiliar with a country, the main point of reference is the trade fair, the place where the first contacts are established and then continued with more in-depth knowledge and targeted visits.”

Emiliano Terreni

Alberto Buffonini

Installation and after-sales missions

He loves his work, believes in uncompromising precision, and is attentive to every single detail. Until the client is satisfied, he does not leave. Davide Spessa is the traveling employee for Gusbi. A figure whose performance is, by nature, itinerant and for whom it can be said that there is not even a usual place of work.

Davide Spessa, what is your connection with Gusbi?

“I am 41 years old and have been working at Gusbi for 15, with prior experience always within the footwear industry. I used to manage a small servicing business with my father in the shoe- machinery field. Once it closed, having already established previous contacts with Giancarlo, I agreed to work with him and here I still am.”

What are the reasons that lead you to be so satisfied with your work?

“I am passionate about my work because it is fun, it allows me to meet many people, to gain a lot of experience. Traveling has changed my life, given me the opportunity to get to know different realities. My activity is sometimes easier and sometimes more complicated, depending on the place and the job order, however, it generally gives me great satisfaction. I have to know how to interface with people from different parts of the world with different habits and, depending on the size of the companies, sometimes directly with managers, sometimes with workers with different levels of preparation.

I take care of the assembly phase of the machine once it arrives at its destination, testing, training until it goes into production. A lot of patience is required. It takes an average of two to three weeks away to complete the work, however the relationship with the client continues over time in order to optimize the use and knowledge of the machine. As in normal life, a human relationship is established with some clients that is meant to last. I’m always on the road, so you just happen to find me in the company today! This year I have already been to Mexico, then to Argentina, Vietnam, China, India, Tunisia, and soon I will return to Tunisia. That is why it is so difficult to find mobile employees, a problem for us and for other companies in Vigevano. Instead, once you get over the hesitancy, you soon realize the personal enrichment and satisfaction you feel when the machine where ‘you put your own into it’ begins to work.”

Davide Spessa

The new leverage of the technical office

Matteo Bianchi, the third generation, is the son of Marco and the cousin of Irene. He studied mechanical engineering at the Milan Polytechnic and joined Gusbi after graduating with a master’s degree in April 2022. At first he considered the possibility of an experience abroad, but then joining the family business, which he had been breathing since childhood, was natural.

Matteo Bianchi, what does it mean to carry on a family tradition?

“It means learning to work in the company, to understand its dynamics and potential. It means being able to gain an all-around educational experience. I started in January 2022 on a part-time basis because I was finishing writing my thesis in English on a topic related to the effects of heat treatments on the behaviour of special steels. Once I graduated, I continued full-time and started working as a mechanical draftsman. I accompanied Davide on some of his trips abroad to get an insight into the installation and machining process of our machines. It was a crucial experience not only to understand how they work and any design errors, but also to learn about realities far removed from our own and to grow on a personal level. The paths of study taken by the third generation (we also await the entry of Benedetta, my sister, as soon as she graduates with a degree in Business Administration with a focus on business management) are aligned and consistent with the needs of the company. The continuous comparison with the experience of those who work in Gusbi is worth more than our last name, as Irene claims. There is certainly no lack of passion. In short, we are here to move forward.”

Matteo Bianchi and the technical office