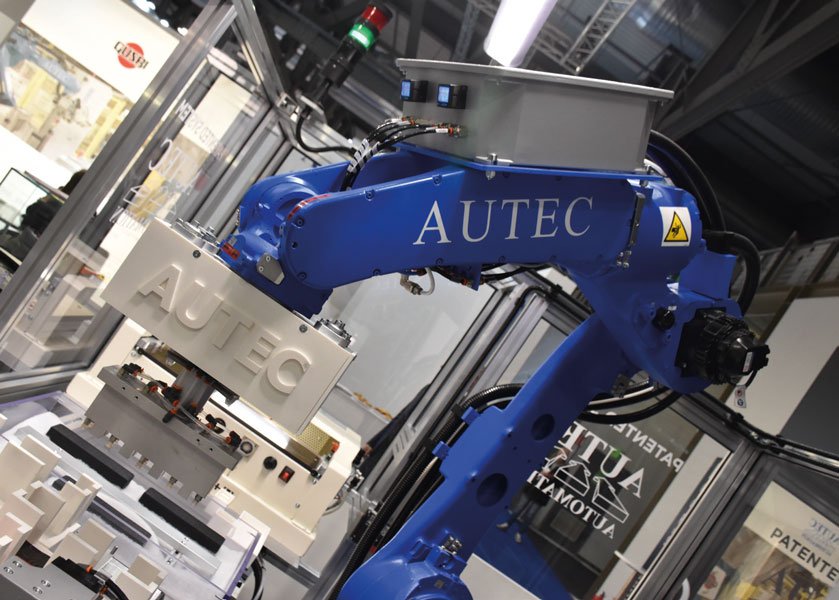

Autec Automation Italian company specialized in the automation of manufacturing processes in the footwear, leather goods and automotive sectors

Autec, Italian company specialized in the automation of manufacturing processes in the footwear, leather goods and automotive sectors, has been standing out for its commitment to the search for customized solutions, designed to guarantee a marked improvement in terms of effectiveness, efficiency, and production quality. During the lockdown, the enterprise rolled up its sleeves and focusing on R&D, that is, activities that resulted in the filing of two new patents and in the development of machines that are easier to handle and to install.

“If I had to take stock of this year’s things and performances,” explained Autec Automation’s Francesca Geri, engineer, “I would say that, work-wise, we registered some positive results, as paradoxical as it may sound. The Covid outbreak undoubtedly caused us some trouble, at least at the beginning: as a matter of fact, back then, we were about to carry out some projects/orders, promptly put on hold; furthermore, in the same period, we were striving to arrange the installation of some machines abroad.”

The pandemic has definitely affected the firm’s schedules and goals, and yet, Autec Automation succeeded in investing more energies in projects that were never completed in “normal” times: “Back then we were too busy dealing with numerous installation projects, so it was basically impossible to devote time to certain activities. During the lockdown, on the other hand, we managed to develop a new software for the scheduling and monitoring of orders on rotary machines used in the footwear sector (more specifically, for the making of soles). For the first time ever, all our resources were “at home” and we chose to pour more efforts in R&D initiatives. After several tests, we were ready to file two new patents!”

Mobility was seriously compromised as well, thus forcing many companies to resort to smart working and to innovative, different technologies. “Travel restrictions led us to reconsider the way we work, leading us to manufacture more standard machines, “easier” to install. During this year, we have managed to carry out more installations remotely. Today,” stated Francesca Geri, “after a year marked by the pandemic, it seems that the market is getting ready to invest again…Let’s hope we can reap the benefits of our work as soon as possible!”

www.autecautomation.com

Francesca Geri