BIBO: unprecedented innovation in the leather goods machinery sector.

In the heart of traditional Italian manufacturing, in the city of Vigevano, lies a company that stands out for its excellence and innovation in the leather goods machinery sector: BIBO. Founded by Gianfranco Biffignandi, the company has established itself as a leader in the field of automatic leather processing machines, offering advanced solutions for cutting, die-cutting, dyeing, gluing, printing and loading/unloading.

The new product presented at Simac Tanning Tech is the proud among the product range of the company, offering an unprecedented level of automation. “We have achieved the goal of making every manual action fully automatic,” Biffignandi explained. “We have developed a system that regulates the engraving depth on the leather in a uniform way, using PLC memory technology. The machine, equipped with four programmable rotary molds, automatically adjusts the pressure according to the size of the plate on each head. This innovation has generated great interest and appreciation from our clients.”

Full automation of leather goods machines is a growing trend, which is spreading thanks to new 4.0 technologies. “Our machines can be programmed remotely, eliminating the need for highly specialized labor,” the founder and president emphasized. “Today, thanks to these technologies, machines can be programmed directly from the office. This allows us to meet the challenges of an uncertain and fluctuating market where it is difficult to find skilled labor, offering innovative solutions that are adaptable to the needs of our clients.”

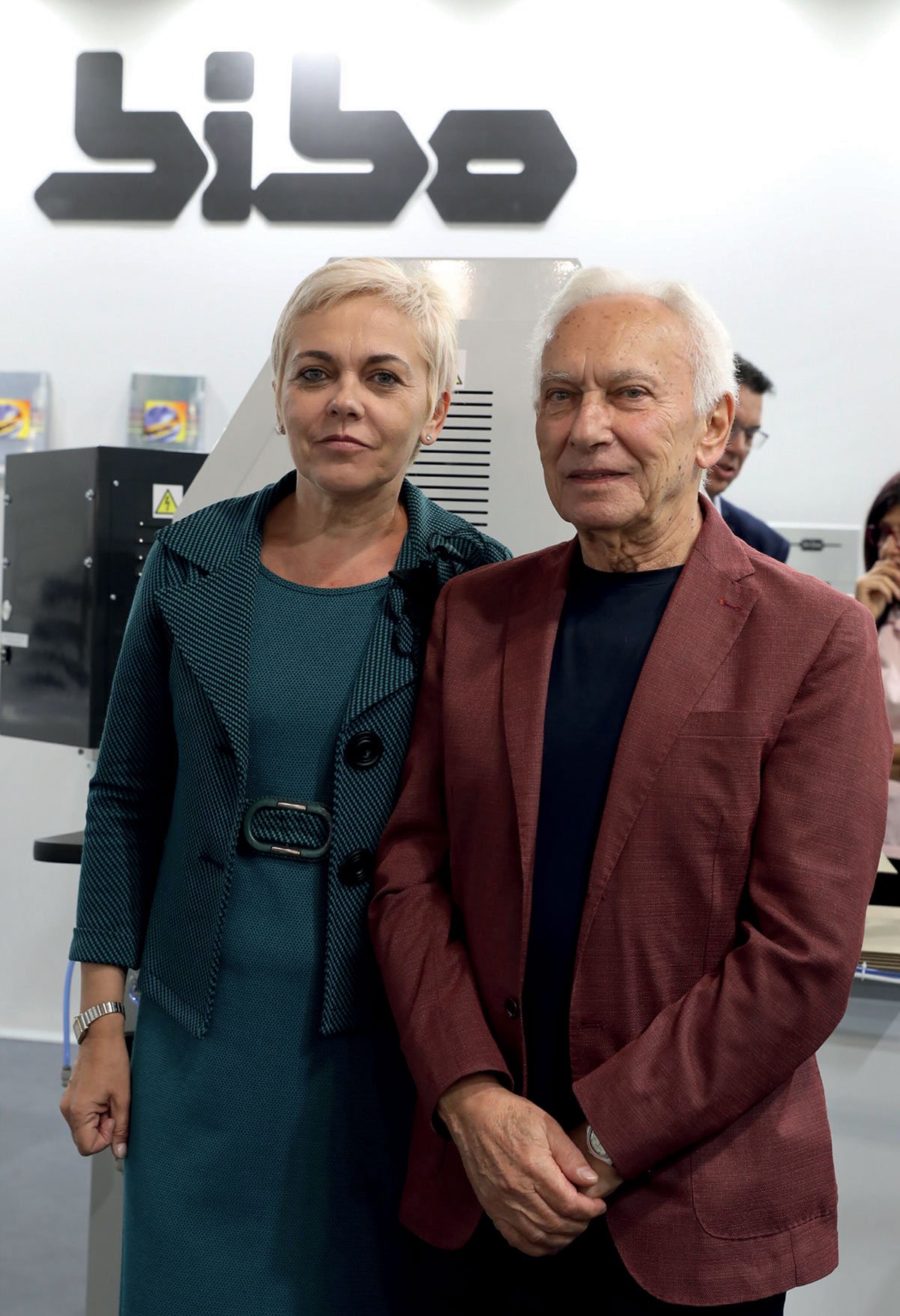

Nadia and Gianfranco Biffignandi at the BIBO stand at the latest edition of Simac Tanning Tech