The tanning process with chromium salts was applied precisely in 1923 in Arzignano for the first time. The process and its patent were developed in the United States at the end of the 1800s but arrived in Italy at the beginning of the 1900s.

But how did knowledge of this process arrive at its subsequent application?

The answer came from Giuseppe Meneghini, descendant of one of the oldest dynasties operating in the tanning sector. At the beginning of year 1923, Mr. Angelo Verza from Arzignano, upon returning from the United States, confided to the young Giuseppe Meneghini (1900-1963), grandfather of the current Giuseppe, that he had seen the hides treated with a new chemical compound. Giuseppe Meneghini was the son of Luigi, descendant of a family that has practiced the art of tanning as early as 1700 in Vicenza and its province, was already operating in the tanning sector in Arzignano in the 19th century. Verza had been in New Jersey as a guest of his emigrated brothers who, having met fortune, were owners of an important leather industry. For a few years in that tannery “chrome” had been successfully used as a new tanning agent. The news was immediately taken as an overseas extravagance, but Meneghini, intrigued by the important potential advantages, persuaded his father to try some tests on an experimental basis in his factory. The practical results were not entirely satisfactory at first, however, even if with difficulty, they came anyway. The Meneghini tannery gradually abandoned the old tanning with vegetable tannin to increasingly develop the chrome tanning one. It was the first in Arzignano and likely in Italy. At the end of the 1930s Giuseppe Meneghini, by then an expert, managed to persuade the Brusarosco cousins, owners of the well-established homonymous tannery, to adopt the new process by becoming partners through a very first example of the transfer of technological “know-how” with the contribution also

of expert professional figures and innovative machinery. It must be considered that in Arzignano, the Guida Elenco dell’Associazione Italiana dell’Industria e del Commercio del Cuoio di Torino (List Guide of the Italian Association of the Leather Industry and Commerce of Turin) in 1907, indicated that only three “real” tanneries were operating in Arzignano: Meneghini, Brusarosco and Carlotto. It will be necessary to wait for the end of the Second World War to finally see this process develop in the entire tanning sector of Arzignano and transform itself from an artisanal activity into an industrial one. This very important discovery caused a real revolution in ancient art. Since then, the new tanning took on great importance

increasingly replacing vegetable tanning, especially in the production of soft leather for uppers. The modern process made the chemical and technological operations considerably shorter and even easier, with savings of tanning products of vegetable origin. All of these factors and the almost contemporary invention of special machines such as the splitting machine, the shaving machine and the staking machine, which made it possible to process a greater number of hides, favored and encouraged the spread of the activity. The nephew likes to remember, with a pinch of pride, that history has always been marked by men who, with their foresight, enthusiasm, imagination, perseverance, commitment and humility, have marked important milestones in life and in their profession. The milestone reached by his grandfather is the synthesis of an aphorism of Trilussa that he had made his own entrepreneurial conduct. …..“if you insist and resist, …..you will reach and you do conquest”…..

A legacy that the current Giuseppe has always pursued, always analyzing, in tackling new projects, in every stage his professional career had reached.

But what was the first chrome tanning process like?

The working method, which could be defined simple as chemical theory, was not easy from a practical point of view. We started from sodium dichromate, an orange-colored hexavalent salt, which was available on the market in the form of dehydrated flakes. As everybody knows, chromium, in order to carry out a tanning action on the skin, must be reduced to a green, trivalent compound. The products with a reducing action previously used were white flour, molasses, glucose and sawdust depending on the recipes. The other ingredients were sulfuric acid, the well-known “fuming oil” and water. In the early days, the operation was carried out in large tubs with wooden slats, which were regularly burned slightly. First the dichromate was dissolved, to which the sulfuric acid was added very slowly. The well-diluted reducing agent was then added to this solution, which was already quite hot. The reaction, calm at the beginning, soon became turbulent due to the high temperatures and the gases which developed. Control was often lost and for this reason the final product was not always the same. The result was a dark green chromium sulphate, rich in aldehydes and organic acids. The tanning formulas were a trade secret kept in store by the custodians and only rarely sold.

Giuseppe Meneghini

Giuseppe Meneghini 1900-1963

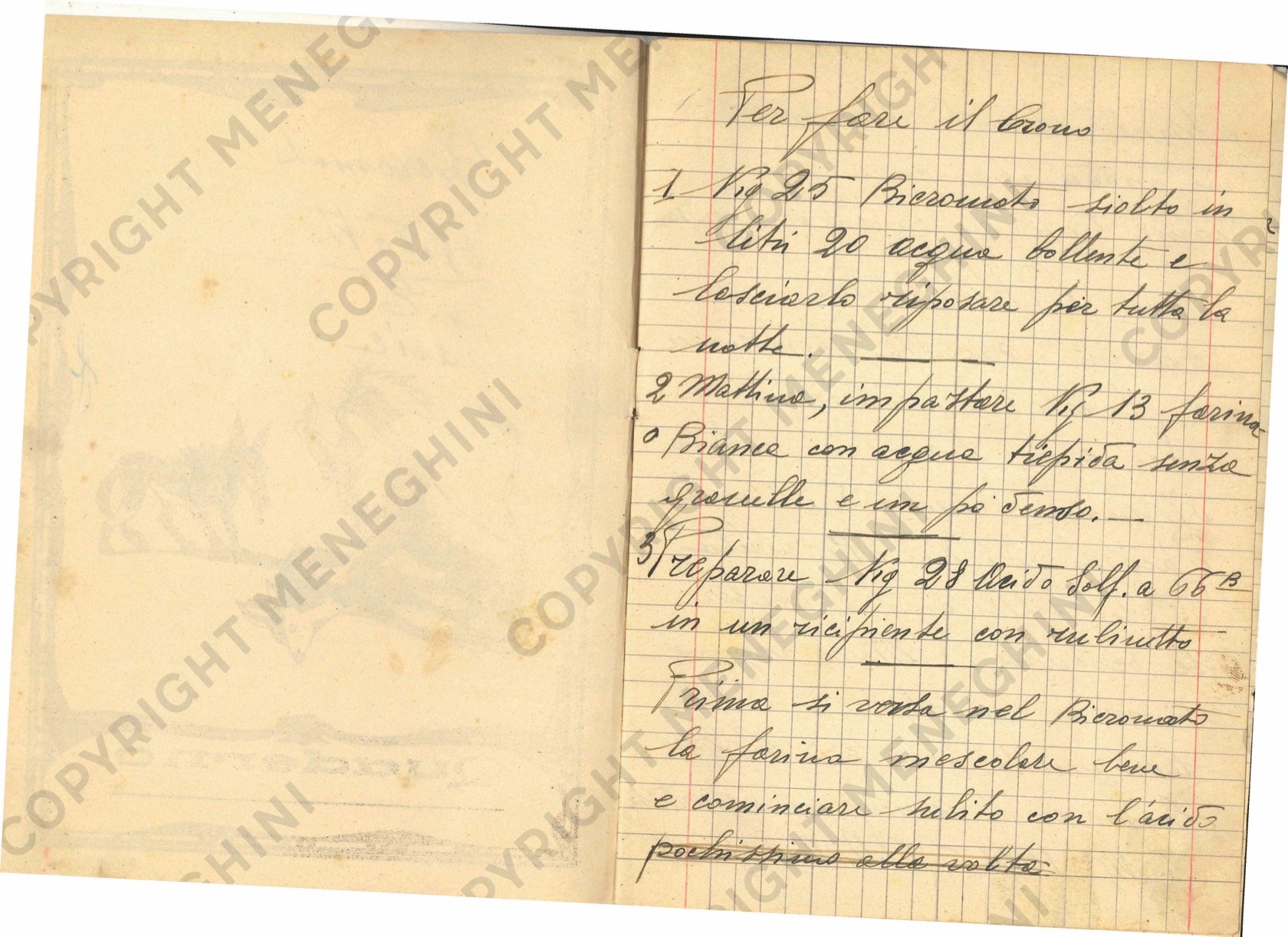

Here, some documents about one of the first formulas in use in Arzignano.

The recipe was taken from an autographed manuscript by Giuseppe Meneghini, handed down and jealously preserved by his nephew; it was used for the chrome plating of hides from national slaughterhouses:

“Put kg. 25 of sodium dichromate in 20 liters of boiling water.

Leave to soak overnight. In the morning knead kg. 13 of white flour with a little warm water.

Meanwhile, prepare kg. 28 of sulfuric acid at 96% in a container fitted with a tap.

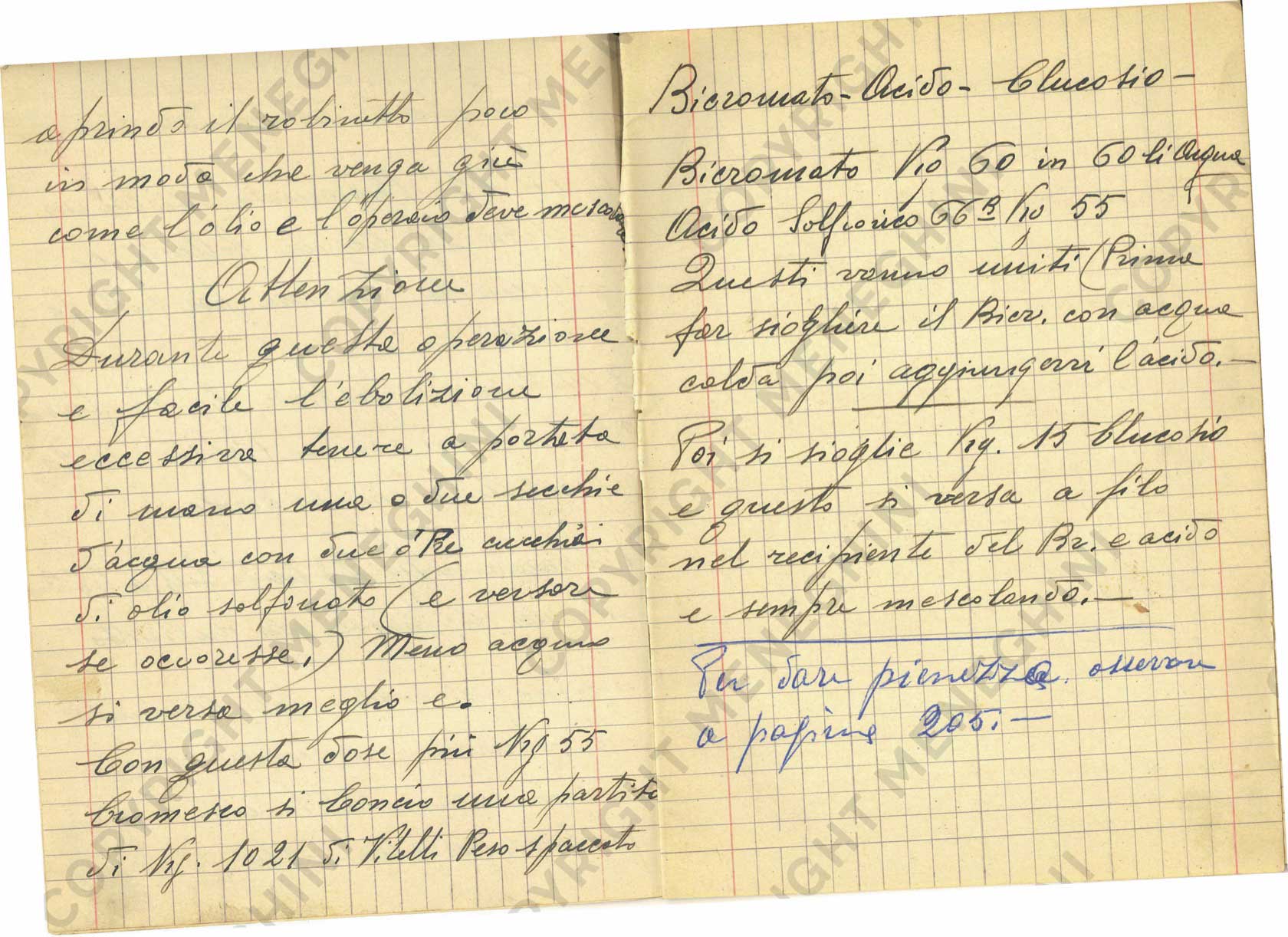

Pour the flour mixture into the dichromate solution and mix, then, opening the tap slightly, slowly let the acid go down, as if it were oil, and continue mixing.

Keep one or two buckets of cold water close at hand (to which two or three tablespoons of sulphonated oil will have been added) for possible dilution in the event of a violent reaction or boiling”.

“With the obtained chromic solution, 1021 kg. of split weight hides can be tanned; it must be added in two installments with an interval of half an hour”.

In 2021 the homonymous grandson, son of Luigi (Luigino) who was the owner of the Giumen Tannery, with the pioneering force of his family, became the promoter of a patent of innovative tanning in the Arzignano area and developed it with the use of zeolite as a tanning product. Also in this case, after initial difficulties in setting up the tanning process, Bioprotech Italia, owner of the patent, succeeded in introducing this new process into the market thanks to an agreement for the transfer of the patent to a multinational company active in the sector. The commercial development of this new processing definitely started. This all allowed the tanning sector to evolve further with an innovative tanning eco sustainable process, similarly as it already happened before with the chrome one, at the beginning of the last century. Giuseppe himself, attentive to eco sustainability of the entire tanning sector and its residues, had previously developed operations to reuse the waste of other sectors including the paper industry through a collaboration with a partner who has allowed the creation of an innovative patented paper (25% made of leather) currently used by many brands in the fashion sector for their own packaging and that of bio-polymers, always with a primary partner, with the creation of a range of bio-polymers which are composed of leather residue up to 50%.

Other projects are now being studied and their feasibility being analyzed. But that’s another story…..

(data font of some parts: “The Art of Tanning” by Fernando Zampiva, Egida Edizioni, printed in 1998)