CIM ITALY is satisfied with the results achieved and has clear ideas for the future: to affirm the logic of the service and focus on a sustainable development

Stefano Innocenti, CIM Italy’s CEO

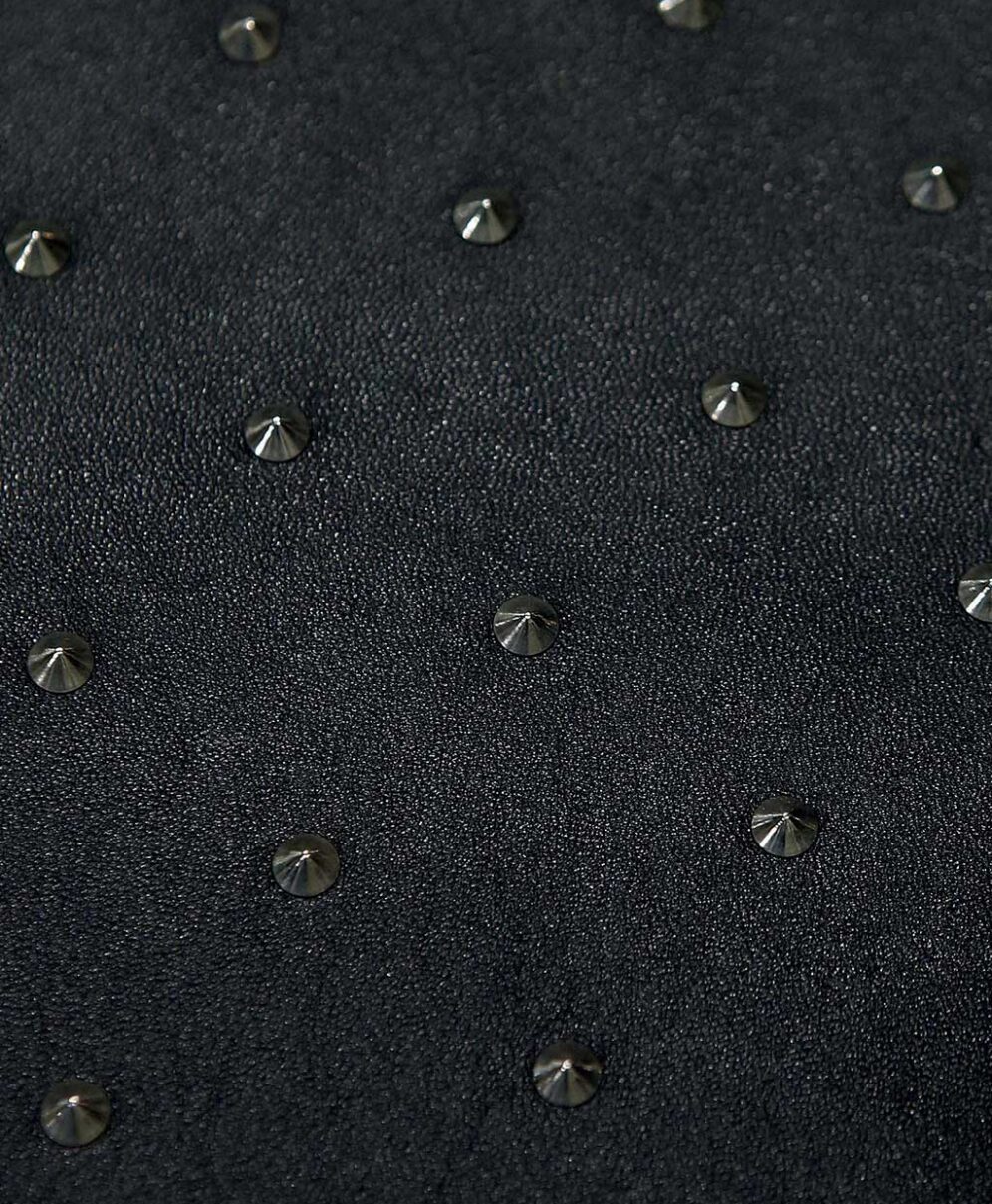

“We are optimistic not because we are forced to, but because we believe in it”. These are the words of Stefano Innocenti, owner of CIM Italy. The Lombard company, specialized in the creation of studs and small parts for the fashion industry. “What happened certainly had an impact, but for us it was very limited: to date, the company turnover is around 15% less than in the same period last year. It is almost a miracle considering that the fashion and luxury chain has suffered significantly. Such a decline comes after years of great growth: that’s why this result makes us happy for the current situation and confident about the work we are doing. We are still carrying out research, as before the virus spread; as a matter of fact, the lockdown has given us some respite and more time to think.”

In your opinion, why were you able to contain the drop in turnover in a market that has experienced such a contraction?

Because we have an international vision: we are not focused only on Italian districts, but we rank customers in the United States, Europe and Eastern European countries, India, China, throughout the Far East and North Africa. A strategy that contributes to the result and helps us in a compensatory logic. Not least, because we’re really good at relating to the customer effectively. We are an all-round partner and we try to give the best service in the shortest possible time. When we are asked to do something we believe is not part of our DNA, we direct the client towards a group of companies we share the same values with, providing them with a sum of skills that can multiply. An added value that, in my opinion, should represent the future of the Italian market.

What are your sustainable development goals?

We are able to meet all fashion’s requires, we are taking the necessary steps to obtain both process and product ISO certifications (Covid has postponed the process for six months), we have fled some patents and improvements to create an eco-sustainable offer. The metal that makes up our items is 60% recycled, the same goes for plastic, and we are replacing some of the plastics and acrylics parts with wood from industrial crops. The goal is to create a 100% recyclable product line, part of which can also be fully disposed. Our machines, originally from Italy or Europe, fulfill the Industry 4.0 features. We have reduced by 70% compared to a couple of years ago the costs of supply and electricity consumption by switching to a free supply contract and replacing the entire lighting system (from neon to LED) within the company. The attention to materials saving and recycling is unconditional.” www.cim-italy.com