Higher productivity and top-notch performances: Comelz has been investing in the upgrading of its range of machines.

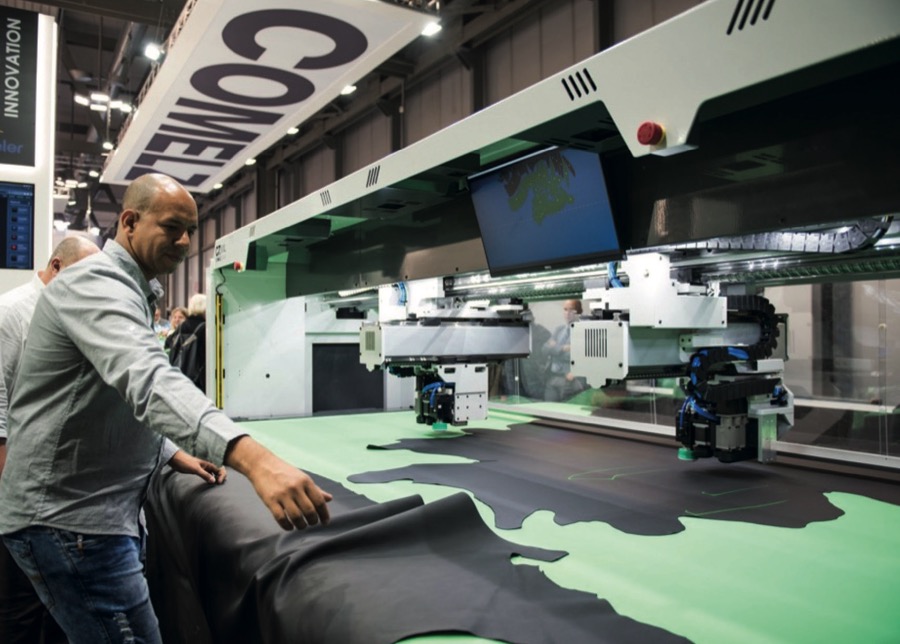

Comelz, renowned company based in Vigevano and specialized in the production of automatic cutting machines for leather and fabrics, set up a large stand at Simac, that caught the attention of plenty of industry professionals. With a keen eye for digitalization, the enterprise put on display its flagship machines, that is, the CZ cutting islands, featuring significant upgrades, as confirmed by the addition of the term Plus to their name. “We already showcased these technologies when they were still prototypes, now they are ready,” explained Paolo Riccardi. “We have chosen to use the word Plus because, even if they fall into step with tradition, these are new machines, featuring top-notch flexibility and versatility standards in order skilfully perform cutting operations on both leather and synthetic material.” A strategy pursued to fulfil the demands of a market on the lookout for increasingly comprehensive solutions, designed to be used not only in the footwear industry. “We have paid close attention to versatility.

More specifically, the XL model is equipped with a wider worktable, perfect either for the automotive field or for cutting hides for the furnishing segment; we have also opened up to sectors that previously were not part of our core business. On the other hand, the L version is conceived to cut synthetic material, whose requirements are different; it is provided with a feeder that allows a single person to place the multilayered fabrics on the machine, rather than a roll holder that continuously unfolds multiple material rolls. It is a very compact model, as power supply devices, multi-layered fabrics or rolls are fully retractable, and, therefore, it can swiftly shift from synthetic to leather cutting. It features the same heads as the XL option and one of its assets is that it is managed by a single worker, who kicks off the cutting procedure and then moves to the rear to collect the cut material, thus markedly improving the productivity rate. Besides that, said technologies now have state-of-the-art video cameras, supported by an Artificial Intelligence software so to cut all types of fabrics, even those featuring logos or patterns, and to automatically trim pre-assembled pieces of leather or fabric “.

Technology and innovation, a combination steadily pursued by Comelz: “For us, technological development is a core value that plays a strategic role. The heads of several machines have been completely upgraded in terms of components and cutting- edge software programmes. They are “smarter”, therefore, cutting operations are faster and more synchronized, resulting in more fluid, balanced movements.”

www.comelz.com