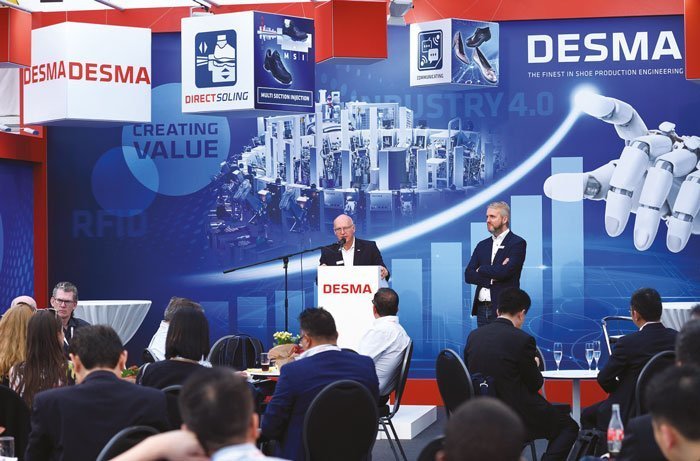

On September 19th and 20th, 2018, DESMA, leading company in shoe production engineering, opened the doors of its Innovation Centre to host a brand-new edition of DESMA House Fair, a one-of-a-kind exhibition providing a comprehensive overview the most pivotal trends with regard to shoe production.

As confirmed by the official data, the latest show broke all records in terms of attendance levels, succeeding in drawing 780 trade visitors proceeding from six continents as well as in hosting 54 exhibitors that encompassed all sectors of the industry supply chain – ranging from prominent materials suppliers and design service providers up to components and shoe manufacturers, who put on display their services, products and innovations, all aimed at putting at the customers’ disposal every possible tool to raise efficiency, reduce costs and improve quality.

Internationally renowned brands and professionals from all over the world gathered in Achim, Germany, to learn more about the latest industry developments with a special focus on topical issues such as automation, customization (applied also to mass production), development of new, lightweight materials, Industry 4.0: as a matter of fact, edition after edition, the DESMA House Fair has grown into the perfect meeting place where to discuss face-to-face about new technologies and cutting-edge solutions, sharing insights and opinions concerning the challenges lying in store for the footwear sector. At the same time, the show manages to provide plenty of fruitful networking opportunities, giving to all the participants the chance to establish new business connections and to catch up with old acquaintances.

DESMA’s “FitStation”

One of the highlights of the latest show was undoubtedly “FitStation”, showcased by DESMA – a feet scanner that sent the analysis’ data directly to the corporate production plant: there, thanks to the implementation of the new multisection injection technology (MSI), it was possible to produce a perfectly customized pair of shoe, individually tailored to fit the wearer, inclusive of the selected colours and design. “The data was collected on the first day of the fair and transmitted to a DESMA production plant in Belgium, so that we were able to present the finished shoes to the amazed guests the very next morning,” said Adrian Strauss, Head of the DESMA Innovation Centre. Noteworthy also the interest aroused by “2018 Concept Shoe”, which combines design, new material, technologies as well as integrated manufacturing in one product. www.desma.de

A focus on DESMA

Established in 1946 in Achim, Germany, DESMA Schuhmaschinen GmbH is specialized in the design and manufacturing of cutting-edge shoe machinery and moulds, especially plants and systems for direct soling – the latter a process in which the sole is injected and moulding onto the pre-produced upper. Constantly at the forefront in terms of research and development of breakthrough solutions able to meet the needs of an increasingly demanding market, the company has been investing significant resources in the automation field as well as in the upgrading of its facilities, thus managing to increase its production capacity and inventories, to improve its lead times and to optimize the workflows.

All the machines sold by DESMA stand out for their reliability, efficiency and ease of use, assembled with the finest materials and equipped with state-of-the-art technologies, in full compliance of all the current regulations concerning safety and environmental safeguard. At the latest edition of the DESMA House Fair, the enterprise announced its plans for the near future, that is, the construction of a new premises with a 12,500-square-meter production area and additional 4,500 sqm. for offices.