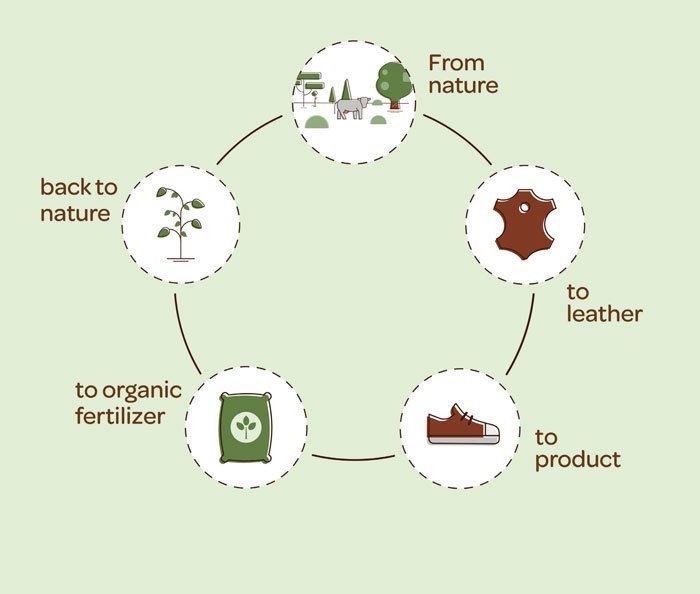

Built around nature’s processes, SILVATEAM’s Ecotan project represents a complete vision for sustainable leather, from its ‘birth’, ‘life’ to ‘next-life’.

Antonio Battaglia

As the world leader in the production of natural tannins, it comes to no surprise that Silvateam chose to base its Ecotan leather formulations on a combination of natural tannins and harmless man made additives. “With this project – states leather BU Director Antonio Battaglia – we wanted to create a new class of bio-circular leathers that are safe for both us and the earth.” Part of this vision meant ensuring that Ecotan leathers are both metal-free and glutaraldehyde-free, as well as avoiding any substance listed in the ZDHC Manufacturing Restricted Substances List (MRSL) and ensuring the safety of both tanners and consumers.

While this may in itself be enough for brands to distance themselves from the issues surrounding mineral and aldehyde-based tanning, the sustainability of Ecotan leathers is not simply a matter of the products used during tanning. For Silvateam, a truly ‘green’ approach to leather must start from the sustainable sourcing of products and go all the way to the end of the leather article’s useful life. For this reason, the Ecotan project follows leather throughout its cycle of ‘birth’, ‘life’ and ‘next life’.

Birth

Silvateam’s nature based approach starts from the main product used during tanning: natural tannins. Sourced from chestnut and quebracho wood, tara pods and gall-nuts, these polyphenolic biomolecules are extracted simply, using only hot water and nothing more. Furthermore, the exhausted wood from the production process is transformed into 100% natural pellets that do not contain additional chemical additives, bleaching or dyeing agents.

In order to demonstrate its sustainable sourcing methods, the company has recently sought successful certification by the Programme for the Endorsement of Forest Certification (PEFC) on its production of chestnut and quebracho tannin, a first in the industry. “The wellbeing of the forests which supply us with this precious resource is synonymous to the survival of our company,” states Battaglia. “This philosophy has been with us from the start and it has allowed us to continue operating sustainably in the same areas for over 165 years.” For example, Silvateam sources 80% of the wood needed for its production of chestnut tannins from an area of 70km surrounding its headquarters in Piedmont, Italy, all while keeping harvest rates below 10% of the forest’s regenerative capacity.

The company hopes that this natural approach will help to further distinguish leather from its synthetic counterparts, which often draw upon dubious claims of natural origin to present themselves as better alternatives to real leather.

Life

While natural tannins are undoubtedly a welcome addition, these efforts would likely fail to impress without the necessary technical performance of the leather. Luckily, even though these formulations share several of the same features of vegetable tanning, they offer much better performance in virtually all areas, from tear resistance to light and heat-fastness. For this reason, Silvateam believes that Ecotan leathers can compete on the same level of glutaraldehyde tanning, and, in some cases, even chrome tanning.

Apart from the aforementioned absence of harmful substances, these leathers also offer benefits for the well-being of our body. “The high hygroscopic properties of the leather which allow it to wick moisture away from our body coupled with the presence of natural tannins help safeguard the balance of our natural bacterial flora, creating an unfavourable environment for the proliferation of bacteria responsible for bad odour formation” states Battaglia. Thanks to this, Ecotan leathers are also particularly suited for insoles and shoe linings, or any other application where leather comes in direct contact with our skin, such as mobile covers, bags, car seats, etc.

Next life

By far the most important step in the life cycle of Ecotan leather articles and scraps is the fact that they can be recycled into a fertiliser for organic agriculture. This was made possible thanks to Silvateam’s partnership with Fertilizzanti Certaldo, leading Italian producer of fertilizers from organic matrixes. Together with specialised finishing company Biofin, part of Gruppo Biokimica, Silvateam was able to create a series of metal-free finishings that do not hamper the recyclability of the leather. Thanks to this coordinated effort, Ecotan leather articles can be transformed into slow-release fertilisers through a process known as hydrolysis which breaks down the leather into polypeptides which intimately bind to the nutritive elements such as mineral salts (Nitrogen and Phosphorus). In this way leather can complete the circle since, indirectly, this fertiliser will help feed the same livestock which nourish the world population and supply us with hides.

Ultimately, it may still be a while before the actual recycling of finished leather articles, since there must first be a coordinated effort towards creating the necessary supply chain and brands must also adapt their designs to allow for the dismantling of the leather. “What we are doing now” states Battaglia “is showing that we have the technology available to allow brands to meet the challenge of the circular economy, so that they can start implementing this into their future designs.”

www.silvateam.it

ecotanleather.com