Andrea Pegoraro, owner EL.PA. SERVICE

Headquartered in Altavilla Vicentina and at the forefront in the field of tanning technology, EL.PA. Service manufactures leather finishing machinery, including the fully automatic testing line (FLL – Finish Line Lab).

E’ positivo il bilancio al Simac Tanning Tech, svoltosi in fiera a Milano nel mese di febbraio, per la EL.PA. SERVICE, l’azienda di Altavilla Vicentina, leader nel settore delle macchine ed impianti ad alto contenuto tecnologico, specifiche per la rifinizione delle pelli.

The latest edition of Simac Tanning Tech, held in Milan last February, turned out to be another success for EL.PA. SERVICE, firm headquartered in Altavilla Vicentina, at the forefront in the hi-tech machinery sector, specifically designed for leather finishing. Established in 1997, the company fell immediately into step with the demand for a prompt, increasingly efficient technical support, in order to meet the customers’ needs effectively and skilfully. Thanks to a steady and gradual interest in the field of technical services for the leather industry, over the years, it has managed to win over the trust of several enterprises, on the lookout for a qualified partner, able to fulfil their various requirements in terms of quality and efficiency. Recently, the Veneto-based firm has succeeded in gaining a strong foothold in the domestic as well as in the foreign market, especially when it comes to the design and manufacturing of finishing and industrial painting machinery.

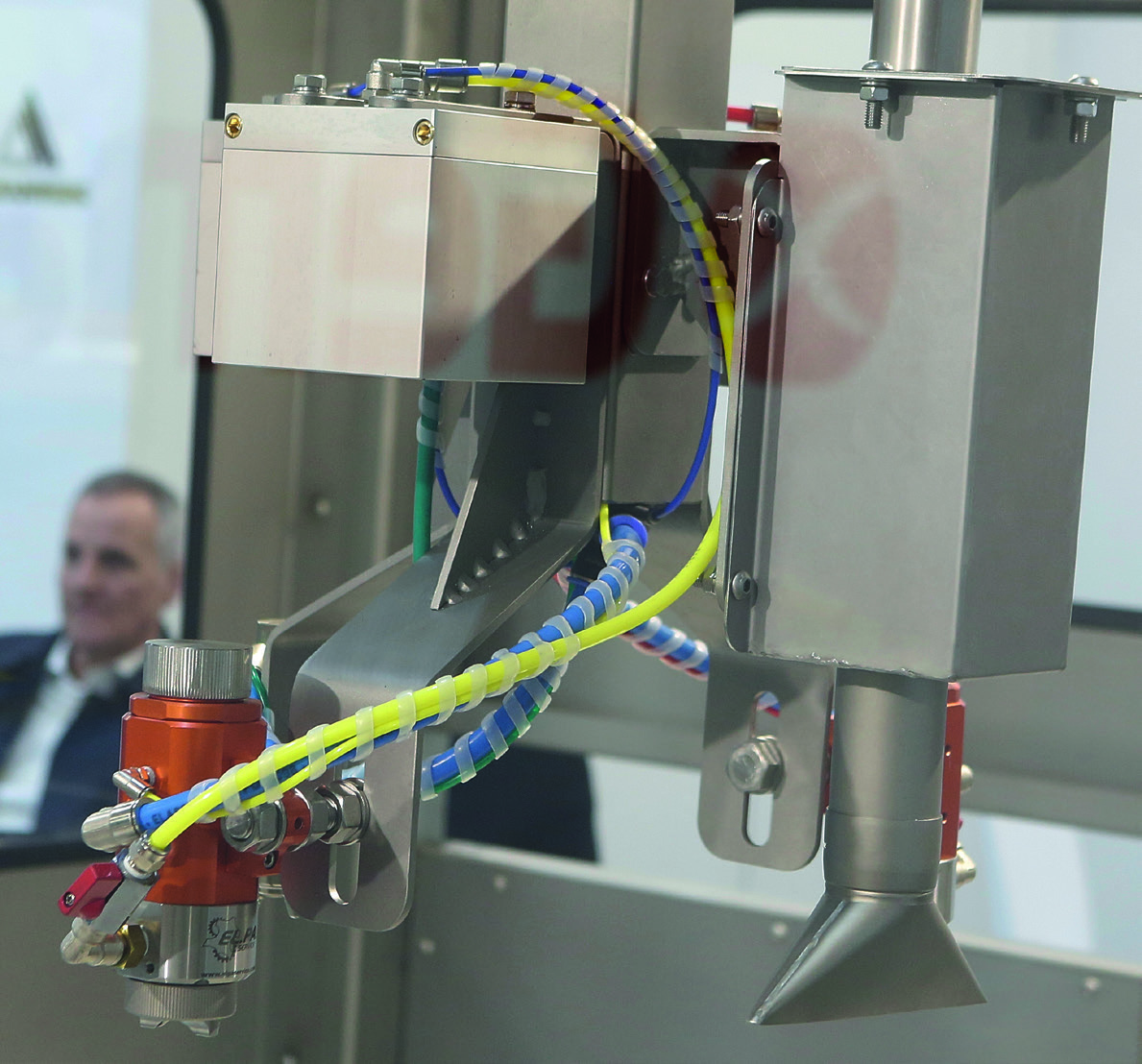

“At Tanning Tech,” confirmed Andrea Pegoraro, EL.PA. SERVICE’s owner, when we met him at the corporate stand, “we have registered a higher turnout, in terms of both visitors and professionals, compared to the previous years. For the occasion, we have launched a world preview, that is, an innovative, modern laboratory provided with an automatic sampling line: it is called FLL (Finish Line Lab) and it brings together, in a single solution, the whole manufacturing process of a finishing line, managed by an advanced software programme. It is not a simple experiment: said plant has been already installed in the Arzignano leather district, as the first model was sold to a prominent company and the feedback has been positive. Production-wise, this technology will become an asset in the years to

come as well. Thanks to this breakthrough model, we have managed to get an invention patent. We are going to develop all the upgrades and customization options required by the clientele, yet we believe that this is a top-of-the-range machine.”

“This “small-sized” spraying line, able to process whole cowhides as well,” stated EL.PA. SERVICE’s owner, “is also the ideal tool to carry out laboratory tests and to deal with small production volumes and pre-manufacturing samples. Technologically speaking, it is a true “gem”, an advanced solution that can be managed via remote control. The innovative concept lies in the fact that the “manual” booth’s classic prototyping phase are no longer carried out manually, since the whole system has been automated, thus resulting in significant benefits concerning not only utmost precision, tests’ repeatability and parameterization, labour costs, but also in terms of low environmental impact. Even though, precision- and repeatability-wise, said system is similar to a finishing plant, chemicals consumption is markedly lower compared to the amount usually employed during manual tests.”

www.elpaservice.com