For the 2020 edition of “Tanning Tech” ERRETRE is pleased to introduce its newest automatic spraying booth model ECOTAN®.

Featuring a brand new type of fully integrated fumes scrubber capable of treating spraying fumes so efficiently to the point of recycling the air directly inside the cabin without the aid of bulky external structures. The design of ECOTAN® series maintains some of the most appreciated features belonging to the ECOSPRAY series, such as the large fully opening doors for easy cleaning and inspection and the wider size carousel for a more uniform spraying coverage.

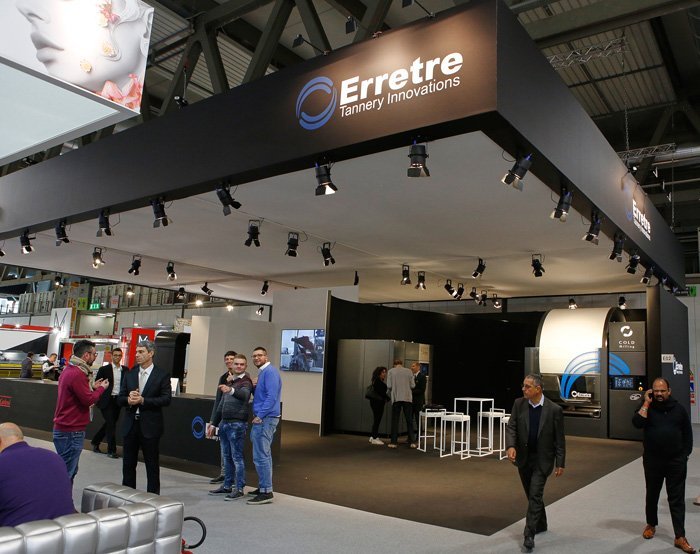

Erretre’s booth at Tanning Tech 2020

This new scrubbing system guarantees improved suction force compared to traditional booths with enormous benefits to the overall inside cleanliness of the cabin. Every operation is easily controlled through a 21” touch screen with a redesigned and intuitive graphic interface which allows to automatically manage sequences of customizable operations such as color change and the maintenance and adjustment of guns. Washing procedures are also automated thus reducing to a minimum the need for manual labor and allowing operators to focus on other tasks.

Every spraying line is equipped with the NER model drying tunnel, also available in the hybrid version with infrared for optimal drying and reduced energy consumption with savings of over 30%. All operating parameters are paired with production information and stored for remote control and analysis according to the “Industry 4.0” philosophy. ERRETRE milling drum featuring Cold Milling® technology will also be presented at the trade show. Cold Milling® is a patented technology which maintains the leather cooler and the air humidity optimal, this recent innovation allows the production of very tight-grained articles. Cold Milling® is available for all drums, from lab scale to large production. The temperature and humidity are meticulously controlled, in order not to affect the most sensitive leathers. It represents the result of several technological breakthroughs and offers many other crust and finishing benefits. Black Line® and Cold Milling® drums are also equipped with the new innovative and user friendly touch screen control. All drums are ready for network connection to our M.O.R.E. advanced scheduler for historical data analysis and interconnection with production managing software to optimize technical and logistical controls. www.erretre.com