Galli Spa takes care and wisely interprets the needs of the leather goods industry, manufacturing technologies aimed at making it more flexible and efficient

Since 1979, Galli has been a leading player in the market for the design, production and sale of leather goods machinery. The company now looks to the future by defining the strategic goals to successfully achieve its mission. The merger with Overmec is the synthesis, but also the beginning of a new identity, which is rooted in the values of tradition by focusing on the technological upgrade. We met Emilio Galli and his son Carlo, respectively president and CEO of the family business based in Vigevano. Their words reveal the image of a company capable of dreaming, of taking risks, of being visionary and innovative.

Emilio Galli and his son Carlo, respectively president and CEO of Galli

How did you cope with this pandemic and what impact did it have on your business? It has been a difficult, demanding year. During the first lockdown we had to interrupt the production cycle, but we carried out all the office activities that could be done remotely, including commercial and training ones. Once back in the company, we focused on respecting the scheduled deliveries and on the moving. As a matter of fact, we recently carried out the merger with Overmec, after having fully acquired it in 2019. Same customers, same markets, same suppliers: an inevitable step towards management and economic optimization that turned to be even more indispensable by the crisis triggered by the COVID-19. A period that caused a heavy impact on the turnover. Fortunately, we are a solid and structured company that has always intertwined opportunity and practicality. We are investing all the available energy, so we do not fear a further weakening for the next year.

How did you structure and arrange the company after the merger? We have transferred and integrated in Galli the commercial, administrative, production, design and 3D modeling offices, made up of 45 professionals. The new research and development division has been placed in the former Overmec plant, where to test new materials, chemicals and technologies. The third site, about one kilometer away from via Cararola 59, is dedicated to the numerical control systems’ production of all the semi-finished pieces that make up the Galli and Overmec machines. Each component is stored in different automatic vertical warehouses, then preassembled and finally destined for the in-house assembly lines. We boast 113 models in our catalogue, so it is a priority to carefully plan all of the processing phases.

Carlo Galli, you are part of the Assomac Council, today chaired by the entrepreneur Maria Vittoria Brustia. What do you think of the work carried out by the association during Gabriella Marchioni Bocca’s five-year presidency? The crucial step Gabriella wanted to take was to involve young entrepreneurs in the leather supply chain by encouraging them to join the Board so that they could start to get to know each other. Gabriella has been able to increase the participation and cohesion of the associates in Assomac’s activities, especially by enhancing the new generations – by definition more motivated in accepting change and collaboration – as a future investment for this sector’s companies.

Do you think that collaboration between member companies could prove to be a double-edged sword? Isn’t it risky to share your knowhow to your competitors? In our sector, still characterized by a strong use of manual skills, secrets are everything. The entrepreneur does not want and cannot reveal his secret, because it represents his advantage over the competition. However, today it is no longer possible to rely only on one’s own strength. The seeds of a new awareness are starting to ripen, there’s a need to create a system aiming at enhancing and protecting not the single district, but the whole Italian supply chain, to the benefit of all trade operators and the entire economy. Big brands must understand that ours is the only country in the world able to hosting a complete and top leather supply chain, a plus that we cannot and must not lose. Through the Association we are able to pursue a common purpose: no longer war between ‘neighbors’ who compete on equal terms, but a united front to access international business opportunities together and counter unfair competition practices. The first step to triggering a virtuous circle is a powerful promotional campaign within the country that lays the foundations of a new leather culture aimed at attracting the attention of young people above all.

What are the factors that add value to the company? The big brands have the design ideas, we offer the technical solution. Creativity, inventiveness is essential in our sector, supported by passion and determination in achieving the result. You have to believe in your own inventions and know how to go against the stream. In our world, the challenge is to build performing, cutting-edge and flexible machines to process all types of materials, including leather which, by nature, is a “live” product, therefore never alike.

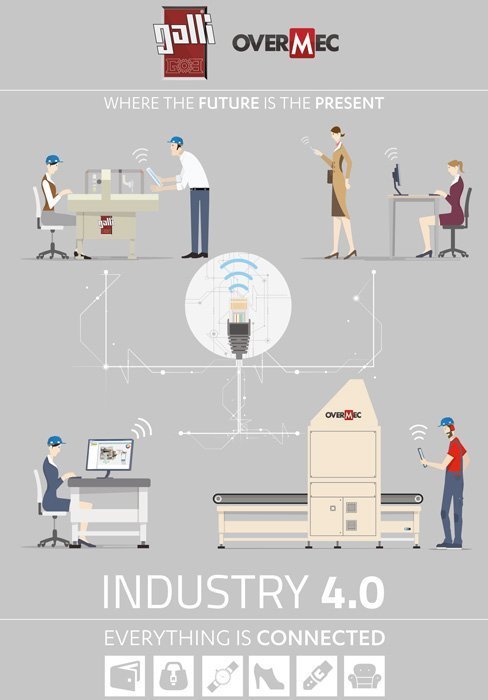

In short, it is necessary to adapt one’s approach to the needs of the leather goods sector, which is still based on know-how. Our technologies support the conservation of the craftsmanship cultural heritage. Galli machines are not competitors of handcrafts, instead they collaborate with it. They streamline the work by eliminating repetitive actions. The other real challenge consists in simplifying the use procedures. Our goal and strength is to make the machine “user friendly” and therefore functional to production methods based on the speed of response to market demands. The aesthetic restyling is also part of this field: we make sure to increase the ergonomics of the machine as much as possible so to let it be comfortable and functional for the operator, without leaving aside safety.

What role does the after-sales service play within the company? 50% of our production is distributed abroad, mainly in Europe. We are structured to intervene wherever requested by the customer, guaranteeing the perfect state of efficiency of the machinery with a rapid and effective assistance, maintenance and updating service, managed by our European and worldwide distributors. www.gallispa.com