GEA GOMMA is Europe’s leader in the production of calendered natural rubber, featuring a cutting-edge, low-impact processing technique.

The sole rubber developed by Gea Gomma is a wholly natural material, processed with a cutting-edge, low-impact technique.

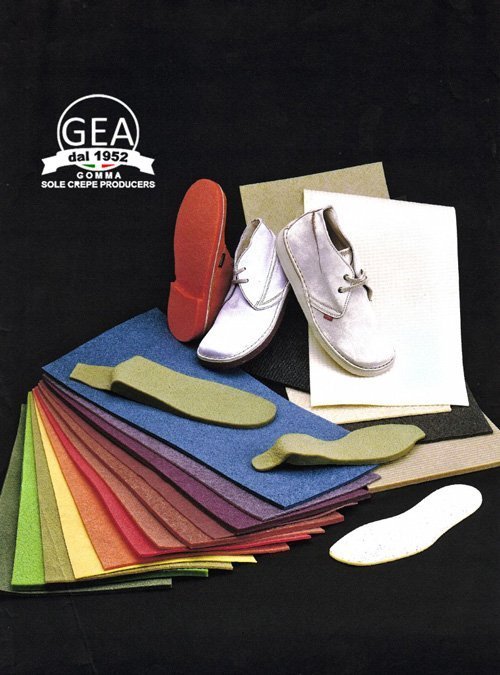

At the forefront in the footwear accessories field, Gea Gomma is a company established in 1952 in Vigevano and currently headquartered in Castello d’Agogna (Pavia province), specialized in the manufacturing of natural rubber sheets to be used in the sole-making sector – a family-run business, in its third generation, standing out on the market for its steady commitment in terms of environmental safeguard and sustainability, as well as for its qualified staff and for its state-ofthe- art processing techniques.

It is a fully eco-friendly, non-polluting manufacturing procedure that allows to turn, without adding neither additives nor pigments, raw rubber – a material derived from the latex of the Hevea Brasiliensis tree, grown in the best plantations in South-East Asia – into natural rubber, so as to get top-quality soles, able to ensure first-rate performances and yield. The final result is an internationally renowned article known as Sole Crepe, exported throughout Europe and widely praised by industry professionals. Unlike other synthetic materials and rubbers, that require highly polluting chemical treatments, the solution provided by Gea Gomma has a significantly lower environmental impact, as it is totally devoid of any solvent and chemical agent: it is a purely mechanical process, conceived to effectively preserve the raw material’s distinctive properties, that does not generate vapours, fumes, dusts and hazardous waste that might endanger the environment and people’s health. Furthermore, the processing scraps can be recycled and re-used in the manufacturing cycle.

This technique – that complies with precise, strict specifications – is carried out in-house, by using mills, mixers and calenders: the ultimate goal is to ensure, on the one hand, the product’s utmost quality, on the other, a solution in line with the current regulations concerning safety and environmental safeguard. Our process is the perfect example of circular economy: even if the waste material is less than 1%, every small piece returns to the working cycle and is converted back. Also the cutting waste we buy from the shoes factories is re-used in the production process. In this way, the soles feature top-notch physical-mechanical properties: besides being wholly eco-friendly and recyclable, they are also waterproof and resistant to abrasion, elastic and flexible, can’t be altered by acidic, alkaline and saline substances. The sheets are available in a wide range of thickness options and colours, the latter resulting from the blend of different types of raw rubber. www.geagomma.it