World leader in the manufacturing of machines and complete lines for the finishing of leather, bonded leather, rubber, paper and imitation leather, last year Gemata has launched GREENFINISH on the market, an innovative finishing system with release paper.

Gemata, company based in Trissino (Vicenza province), has installed the SHORT version at its factory, where we went to observe it better in action. Gemata, renowned partner of tanneries, has launched the innovative release paper finishing system GREENFINISH. To meet the demand of some specific markets, such as that of Santa Croce sull’Arno, where spaces are tiny and production lots are increasingly smaller, Gemata launched GREENFINISH SHORT line with a footprint of only 20 meters. GREENFINISH SHORT is characterized by being a compact and flexible system that ensures a speed of 6-7 m/min, ideal for small production lots.

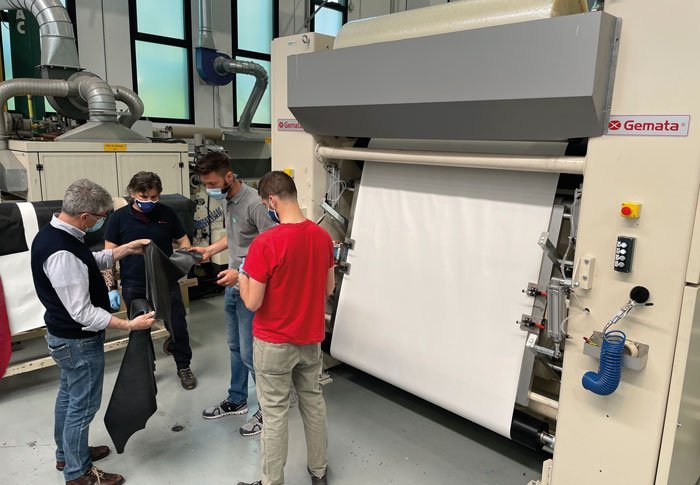

Some months ago, Gemata has installed one of these innovative systems inside the structure that houses the research and development department. The editorial staff of Tannery International was invited to attend a practical demonstration of its particular functions in collaboration with the technicians of Stahl Italia and Chime, Gabriele Fort and Sebastiano Maporti.

In the last two years we have often talked about this type of finishing systems with release paper, in different forms and solutions, which we have found to ensure an exceptional yield and productivity. On the other hand, the disadvantages include the high cost, the large size and the long and complex start-up phase. What impressed us most about GREENFINISH SHORT is precisely the speed of tuning and start-up. As a matter of fact, during the demonstration it was only necessary to adjust the amount of product to be coated and the temperature of the IR drying system: in a very short time we were able to touch high-end leathers, boasting great grain uniformity. The whole plant is also very simple, considering that it uses a GREENSTARs roller coater machine to homogeneously spread the product, both on buffed and full-grain leathers, thus reducing the dispersion of chemical product to zero compared to spray application.

A functional and ecological choice; for years, the attention to environmental issues has been increasingly felt by both the fashion industry players and those of the automotive and furniture industries, who are looking for the most ecosustainable approach possible for products and productions processes. The green feature of the GREENFINISH SHORT is not limited to the coating machine only: this line, instead of using the traditional boiler for diathermic oil, is equipped with an infrared oven, which ensures a significant reduction in the cost of the entire system, but also a saving in the use of it because it consumes only in the presence of passing leathers, also ensuring a dust-free drying and a much easier management.

Furthermore, this solution allows to constantly controlling the leather temperature, which is essential, for example, for metal-free tanned leathers, which require to be dryed at low temperatures.

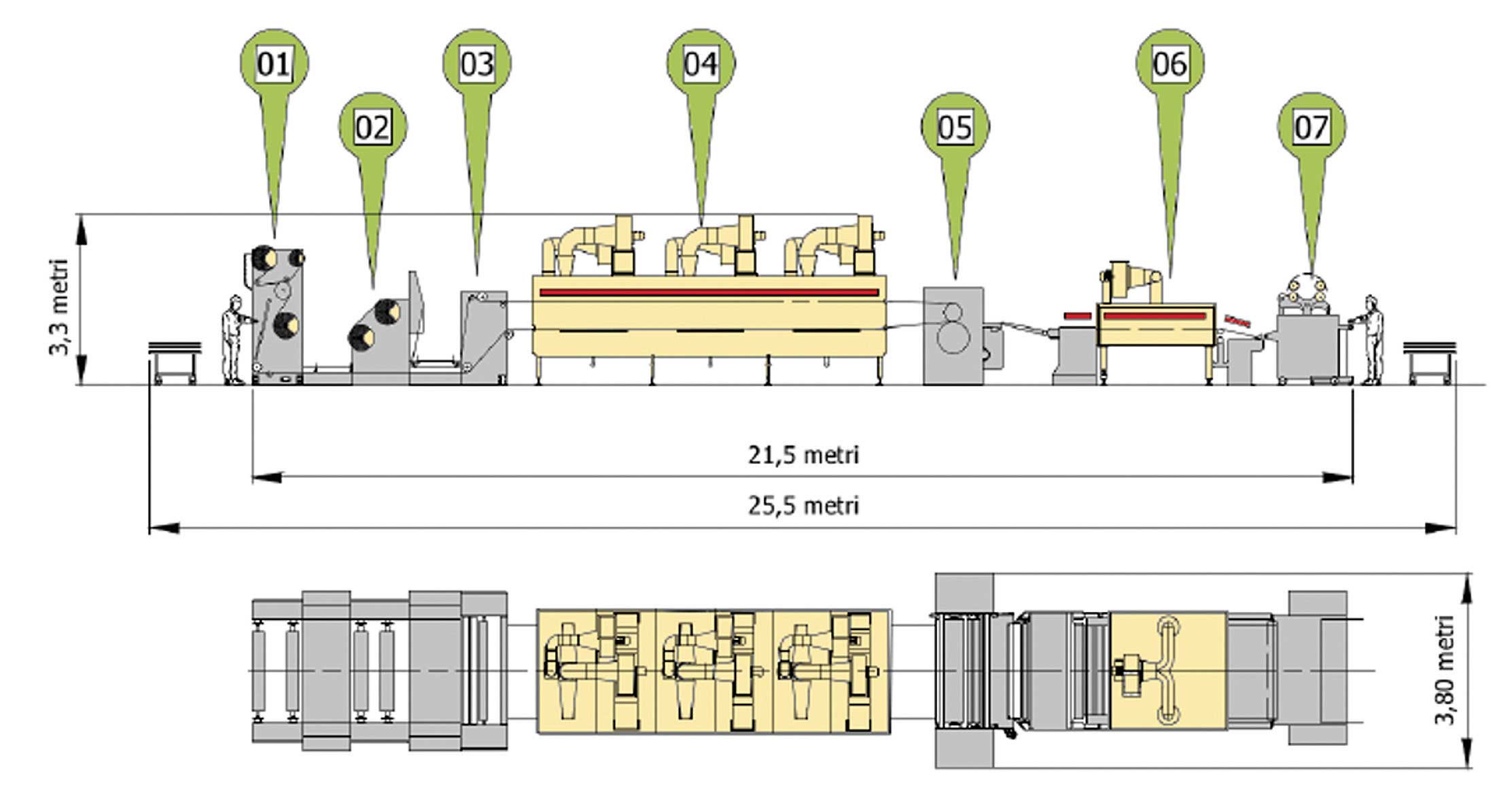

Another very interesting aspect of the GREENFINISH SHORT is its compactness, which makes it attractive for many tanneries often having space lack.

“GREENFINISH SHORT – Gianni Maitan tells us – being only 20 meters long, boasting an autonomy of 1000 m of release paper and a production speed of 6-7 meters / min, is designed for those tanneries which have lack of space, finishing small lots of leather. Thanks to this innovation, Gemata is confirmed as a world leader in the tanning sector also by virtue of ecological and technical innovations and, finally, those concerning the optimization of dimensions: what we have done has been possible thanks to the commitment of us all. Our company can count on excellent human resources and deep partnerships with customers: we constantly collaborate with them to find innovative solutions and to customize technologies according to their needs. This is the strength that let us to always reach new goals and to confidently look to the future.”

www.gemata.com

THE SYSTEM

1. REWINDING UNIT AND RELEASE PAPER CLEANING

2. UNWINDER AND PAPER JOINING

3. GREENLINE ROLLER COATING HEAD

4. INFRARED DRYING TUNNEL

5. LAMINATION CALENDER

6. INFRARED DRYING TUNNEL

7. GREENSTARs ROLLER COATING MACHINE

Why GREENFINISH?

ECONOMIC BENEFIT

• Low cost of the plant

• Lower production cost

• Only 3 people are required to run the system

• No boiler for the diathermic oil

• Reduced power consumption of drying ovens: the lamps are turned off during the line inactivity

• Right to use the GREEN FINISH® brand

TECHNICAL BENEFIT

• Small overall dimension: from 21 m

• Upgrading of any type of leather

• Temperature control directly on both the surface of the release paper and on the leathers

• Elimination of dust contamination

• Automatic cleaning system for release paper

• Possibility of use of different types of release paper

GREEN BENEFIT

• Reduced power consumption of water and electricity

• No waste of chemical

• Re-use of the release paper more than 30 times

• Zero emissions in atmosphere