World leader in the production of plant-based extracts and tannins, SILVATEAM is the first company commercializing leather tanning products to be rewarded with the forest certification PEFC for its production of chestnut and quebracho tannins.

The PEFC certification is the proof of the commitment and of the attention that Silvateam has been paying, right since its foundation, to environmental safeguard, to the protection of forests and of their communities. The sustainability of the process cycles has been strengthened over the years thanks to the efforts made throughout the supply chain, so as to promote responsible practices, as well as to the cooperation with the authorities in charge, in order to implement a regulation able to guarantee the sustainable valorisation of natural resources.

However, in a world on the lookout for new certainties so as to safeguard the consumer/producer relationship when it comes to the use of sustainable forest sources and in which the tanning sector is constantly under attack, the opportunity to rely on such a renowned certification like PEFC takes to a whole new level the benefits entailed by the employment of plant-based tannins in tanning and retaining operations. As a matter of fact, if necessary, tanneries and fashion houses can give evidence that the leather produced or used has been processed with tannins proceeding from a PEFC-certified supply chain.

Moreover, this goal has given to Silvateam the chance to officially underline both the entrepreneurial commitment in terms of environmental safeguard and the safety in purchasing wood from sustainable, monitored sources. As stated by Antonio Battaglia, Head of Silvateam’s BU Leather, “the tanning sector has to invest in a sustainability-oriented message, able to go hand in hand with the traditional ones concerning quality and durability. In this sector, the vegetable tanning and retanning technologies as well as our Ecotan® solutions designed for the production of chrome-free leather, allow to convey to consumers an unprecedented message in terms of sustainability and low-impact production processes.” Bearing this in mind, Silvateam is cooperating with prominent tanning groups in order to define a clear message when it comes to the sustainability of the tanning processes.

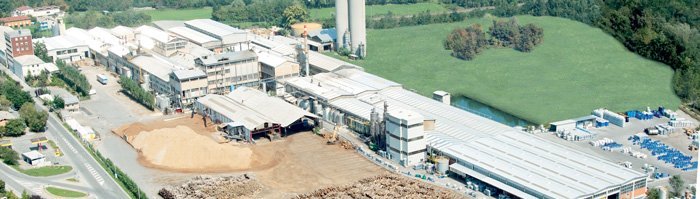

The supply of biomass proceeds both from certified forests and from woods managed in full compliance with the current local regulations. It could not be otherwise, given that, for over 165 years, Silvateam has been working in the same territories. As far as Italy is concerned, for example, 80% of the chestnut wood used for tannin extraction comes from a circular area of 70 km surrounding San Michele Mondovì, Piedmont (northen Italy), where the corporate headquarters is based.

Furthermore, the chestnut tree is a coppice plant widely spread in Italy’s hilly areas, boasting a high regeneration capacity: once cut down at the base of the trunk, the stump germinates rapidly and gives life to new plants. In Argentina, in the Chaco region, where there are virgin forests rich in quebracho (the latter accounting for 10% of the total amount of plants in the average woods), wood cutting is carried out through a so-called selective thinning process that involves only 0.1% of specimens per hectare, thus favoring the growth of younger trees as well as local extensive breeding. Today, the alternative lies in full deforestation in order to provide space for soybean plantations, resulting in the well-known consequences.

Over the years, Silvateam has been carrying out studies and has been developing supply models thanks to collaborations with renowned universities and regional forestry bodies, so as to foster the implementation of responsible practices. This certification puts in the limelight another pivotal factor, namely, the versatility of the tannin, a natural substance that can be used in several end sectors besides the tanning one, like enology, beer and juices production, animal feed and nutraceautical industries. www.silvateam.it