ICF doesn’t stop and diversified its production by investing in sanitizing products and articles for individual protection. A digitalized offer destined to be expanded: “We strongly believe in the value of e-commerce”

The Covid-19 emergency did not stop Industrie Chimiche Forestali’s creativity nor its strong orientation towards the development. Since 1918 the chemical group has been producing in Italy and exporting high-tech adhesives and fabrics all over the world mainly for the markets footwear, leather goods, automotive and packaging.

To tackle the pandemic crisis, the company, headquartered in Marcallo con Casone (Milano province), started to diversify its production through a deep research, fruit of which have been presented at the last edition of Lineapelle. “During the lockdown we were allowed to work thanks to our business identification code” explains Guido Cami, president and CEO of ICF. “This has led us, in such a difficult time, to remain focused and to express our contribution, an opportunity of great human value rather than economic and financial.

Although the first months after the start of the pandemic featured a slowdown of some production sectors that are very important for us such as footwear and leather goods, today we can say that we have invested our energies well: at the end of 2020 we expect a turnover of 60 million euros compared to 70 last year. All without making use of layoffs and regularly paying services and suppliers.”

ICF President & CEO Guido Cami (on the right in the foreground) with his staff at the stand set up at the latest edition of Lineapelle

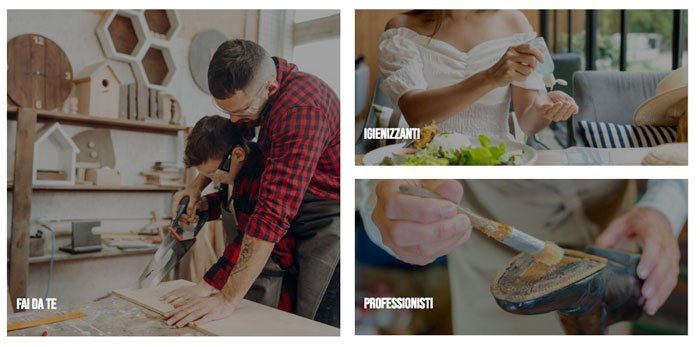

While automotive and packaging are the driving force behind the business economy today, another great resource for ICF is the 100% made in Italy line of sanitizing and personal protection products, made in compliance with the strictest safety standards. The real novelty is the launch last August of the online shop.forestali.it channel where these items are now available.

After the detergents for professional and domestic use for the sanitizing treatment of hands, ViP and ToP, and surfaces, GulP and WoW, after the filtering fabrics for Freedom M1 masks, September 14th marked the launch of the new surgical type II masks Foremask: that’s a medical device made in Ahlstrom multilayer technical fabric boasting a rate of bacterial filtration higher than 98%, high breathability (differential pressure equal to 33 Pa / cm2) and developed in full compliance with the EN 14683: 2019 standard.

“We decided to invest in digitalization and brand awareness – said Guido Cami – because we strongly believe in the value of e-commerce.” Cami’s declared intention is to keep on developing the digital strategy aiming at expanding the commercial goal more and more: news are expected in the DIY and shoe repair and care sectors.

Shop Online Forestali

Among the most virtuous, acclaimed projects from the point of view of sustainability it’s the ContaineRevolution, a transportable container for water-based adhesives, made up of a PVC wrapping and an internal reusable trilaminate bag carrying 50 or 100 kilograms. Once the glue has been extracted with the compressed air system, the bag, instead of being disposed, is returned to ICF which will refill it, thus allowing safe, convenient and ecological management of the adhesive contained.

www.forestali.it