Launched co-invention between the long-established converter of textiles and semi-finished products for footwear and leather goods, Directa Plus is synonymous with graphene nanoparticle-based compounds. Objective: to jointly produce innovative products with high added value

After restoring the foundations of the company’s prosperity and regaining the Olympus of the supply chain linked to top fashion and luxury brands, it is time for Schmid to face and overcome new challenges. The Meeting of graphene- related textile technologies is one of these. On the priority list is the initiation of a collaboration with Directa Plus, one of the world’s largest suppliers of graphene nanoparticle-based compounds for application in consumer and industrial markets. A partnership that can promise products with revolutionary performance for the health and comfort of the end consumer. Valerio Baiardo, general manager and shareholder of Schmid’s new organizational structure, and Directa Plus top executives Giulio and Davide Cesareo, Founder&CEO and Sales Manager respectively, tell us about the most fascinating practical applications of graphene in fashion.

How did the idea come about?

V.B. “The change of course that took place after ensuring financial solidity for the company by absorbing its debt and resolving a capital increase has opened up new horizons. At the product level there are many new things to tap into, and now that we are more serene we are able to approach such challenges with a different spirit. Graphene is a very interesting and very promising material that will enable us to revolutionize the performance of our textile substrates destined for the footwear and leather goods sectors. Innovation must be seized at the right time, and the success of graphene in the sector in which we operate depends on the vision of the creative person with whom we interface, based on his or her sensitivity not only to the aesthetic aspect of the product, but above all to its functional value.”

What is Directa Plus’ graphene first and foremost?

D.C. “Graphene is the name given to a single layer of carbon atoms organized in a honeycomb structure. Diretta Plus products identified by the G+® brand name are pristine graphene nanopatterns obtained through a proprietary method based on the physical transformation of natural graphite. In our production cycle, we start with the mineral we purchase in flakes and expand it through a plasma process at a temperature of ten thousand degrees centigrade (that of the sun’s surface, to be clear). Subjected to extremely high pressures, the flakes explode, increasing the distances between the individual sheets of graphene contained within them. The resulting product, called Grafysorber®, is a production intermediate that has found its greatest application in water purification and remediation activities from hydrocarbons. The third stage is a solution of graphene in water, achieved through a very special technology and used to make a whole range of pastes, including the printing paste used for textile membranes. The last stage is drying where we make the paste finer and finer to obtain 2D graphene nanoplates in packages of 2 to 5 graphene sheets. Among their many applications is in next- generation batteries.

We hold an extremely significant intellectual property package: to date there are 72 patents approved and 28 patents pending for a company with less than 30 employees in Italy and 180 in Romania.”

Which of the many areas of application have you focused on the most?

G.C. “It’s kind of the moment, graphene is coming to the big supply chains. It is an enabling material in countless fields of application, from aerospace to medical. Used in very limited quantities it has major ameliorative impacts on thermal, antimicrobial, mechanical strength and lightfastness performance. However, we don’t want to run the risk of not maintaining the right amount of humility. We intend to focus on only a few areas – environment, textiles, elastomers, composite materials – choosing to work with a number of selected partners in each sector who, like Schmid, know their market and its dynamics well and who share the

Launched co-invention between the long-established converter of textiles and semi-finished products for footwear and leather goods, Directa Plus is synonymous with graphene nanoparticle-based compounds.

Objective: to jointly produce innovative products with high added value same vision as us based on a simple, scalable and sustainable business model.”

So let’s come to textiles. What are the technologies you have developed in this area?

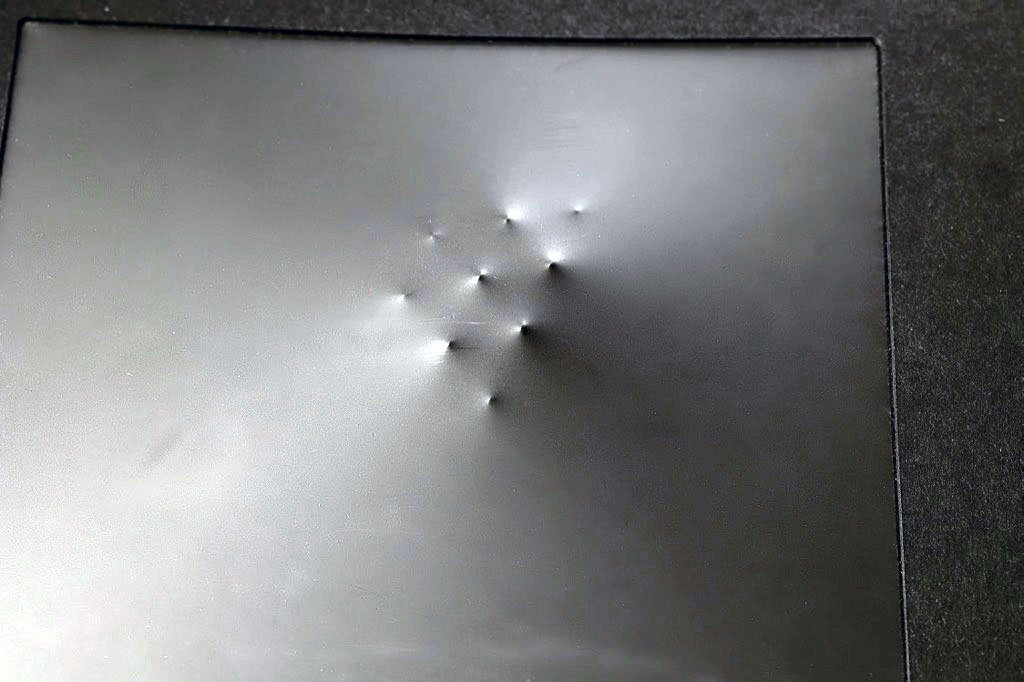

D.C. “There are essentially four: printing, membrane, impregnation and coating. The first, named planar thermal circuitry, involves applying a connected lattice of printing paste containing graphene to a fabric. The advantages are first of all, thermal. In fact, the circuit is thermally active, that is, it is able to redistribute heat from warmer to cooler areas by homogenizing the temperature. It is a technology that works in two directions: it can be applied to take advantage of both a temperature dissipation effect if placed in an “open system,” that is, one that has exchanges with the external environment (e.g., a T-shirt), and a heat absorption and retention effect if placed in a “closed system” (e.g., a jacket or insulation). Finally, it provides antibacterial and antistatic efficacy, which is why this application is in high demand in the field of workwear and safety garments, areas from which our studies and tests started. The membrane, which is of particular interest in the footwear world-can be laminated to different types of fabric, both synthetic and natural fibres, and also boasts an important thermal impact. Introduced inside a shoe or outerwear, it not only ensures the typical performance of membranes (windproof, rainproof capabilities), but above all is able to distribute temperature by homogenizing it. What’s more, tested in a climate chamber, it was found to be very breathable, with an important impact in terms of the user’s comfort and well-being.

More recently, and indicated especially for the lining compartment, is the impregnation technology developed under the Covid emergency: the fabric is immersed in a water-based bath with a graphene component, a process capable of transferring high antiviral and antimicrobial as well as thermal capabilities to the product. The fourth and final technology is a coating, a coating with an extremely smooth structure very similar aesthetically to the membrane, but with the possibility of customizing the performance, for example with transfer papers. It is designed particularly for outdoor furniture and automotive plating, for anything that is subjected to continuous stress. In fact, it is a very durable technology because of its lightfastness and, of course, its’ antimicrobial capabilities.”

What is the added value of the Directa Plus product in terms of sustainability?

G.C. “We have been talking about sustainability from when it was not such a sexy word. We are currently the only company in the world to produce graphene without chemical processes, and we list 42 certifications of no impact on biological systems. We have obtained the Green Certificate awarded by the London Stock Exchange to companies with more than 50 percent of sales positively impacting the environment. This is why we approached the textile industry. Innovation is a continuum: starting with the planar thermal circuit, we are discovering all the antimicrobial, antiviral and antibacterial potential given by the use of graphene in different types of printing. Tests conducted in collaboration with Policlinico Agostino Gemelli of the Università Cattolica del Sacro Cuore in Rome have shown how our graphene inactivates SARS CoV- 2, the Covid-19 virus. The real issue, however, is that our graphene particle, because of its particular morphology, cannot penetrate human cells and impair their functionality.”

What are your certifications in textiles?

G.C. “We are working on the G+ logo because we want the consumer to identify Graphene Plus as “the good one.” We have tested G+ textiles in vitro and in vivo: they are hypoallergenic, they do not release nanoparticles. They comply with the requirements of the ZDHC MRSL. We have achieved Eco Passport by Oeko-Tex® certification. We are ready to meet the needs of our partners in the most credible and transparent way.”

What Schmid products can be tapped by Directa Plus technologies?

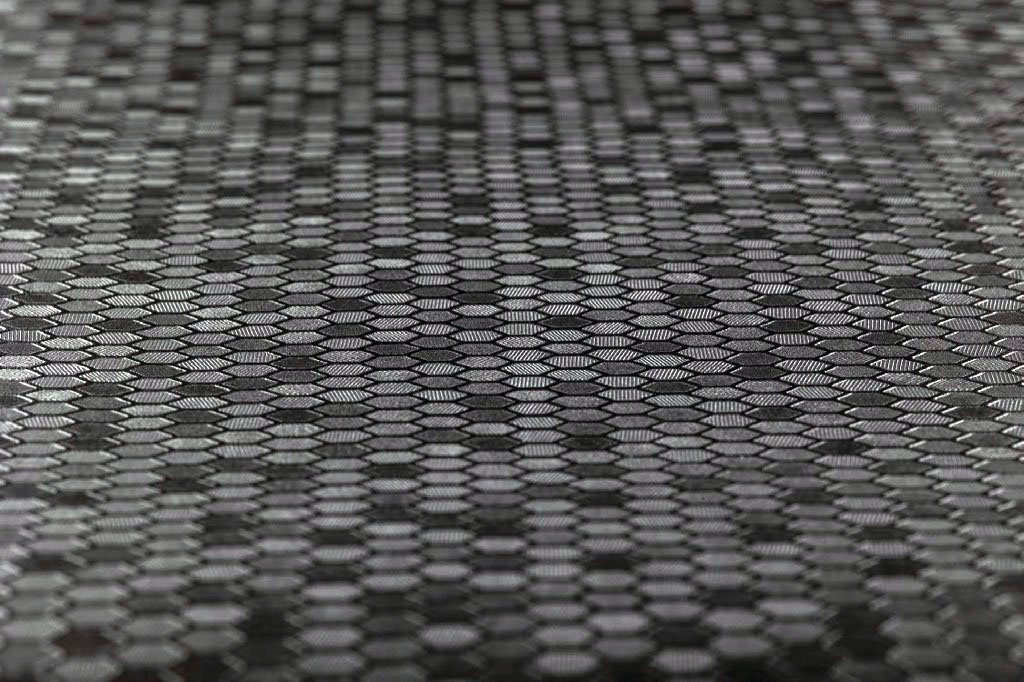

V.B. “At the moment, the upholstery segment leads the way. In my opinion, as far as our product is concerned, it is in that sector that graphene is able to express its full potential and ease of use. The closed-loop lattice effect, which can also be printed on a colored base, can be a pleasing graphic motif in a variety of contexts, from a satin-lined backpack to the upper of a sports shoe. A motif, that of the lattice, which can be customized with a brand logo, for example. Our role as a converter is to ennoble fabrics not only aesthetically, but also in terms of performance. In short, we supply the fabrics and Directa Plus turns them into ready-to-use solutions in collaboration with the creative needs of the designer.”

Does this ennobling cost a lot of money?

D.C. “As long as the volumes are small absorbing the cost of an innovation becomes difficult for the customer but, as always, when economies of scale increase, prices are bound to go down. Although it is well established that applying premium price to a beautiful, technological product that makes the user feel good is a strategy that pays off.”

What are the limitations of graphene?

V.B. “The drawback of this material with extraordinary qualities lies in the color offering, which, referring back to graphite, remains in shades of grey. However, I do not consider this a negative connotation, but an objective limitation of the material. In my opinion it is even a plus that ensures its credibility. It’s just a matter of adapting the style to the constraints.”

G.C. “We are testing the use of pigments to achieve color variations, but we have to be careful that the makeup operation does not negatively impact the performance of the material. Because we want to sell performance.”

The meeting at Schmid: center Valerio Baiardo with Giulio Cesareo (left) and Davide Cesareo

The different stages of graphene processing Directa Plus

Schmid of San Giuliano Milanese

A thermogram of the planar thermal circuit in action

coating

printing

impregnation

membrane