Nastrotex-Cufra fights back against the crisis by investing in product and process sustainability

For almost seventy years, Nastrotex- Cufra, leading company specialized in the manufacturing of elastic tapes for underwear, sportswear and footwear, has been building its success on a wellestablished know-how and on its ability to innovate. In this context affected by the pandemic, the Lombardy-based firm does not miss a beat and outlines the future of elastic tapes, integrated with innovative materials, as well as strategies to handle such a volatile situation. An endeavour explained by Barbara Cucchi, owner of the company together with her brother Roberto.

Barbara Cucchi, how have you managed the impact of the Covid-19 pandemic on your business and on the employees? The pandemic has deeply affected the corporate economy as well as the cash flows. In the early months of 2020, Nastrotex-Cufra registered a drop in turnover by 70% compared to the same period in 2019. We implemented several countermeasures concerning, in the first place, the employees, by resorting to redundancy funds. Furthermore, we experienced not only a marked decrease in non-strategic costs and in consultancy activities, but also the optimization of raw materials purchase operations, due to a more careful analysis of the stock turnover rate.

In this period, how have you taken care of your customers? First of all, we have guaranteed scheduled deliveries, whenever possible. At the same time, we have introduced supply solutions at controlled prices: on the one hand, to reduce the surplus stock available in the warehouse, while, on the other, to provide customers with a prompt, quality service at competitive prices.

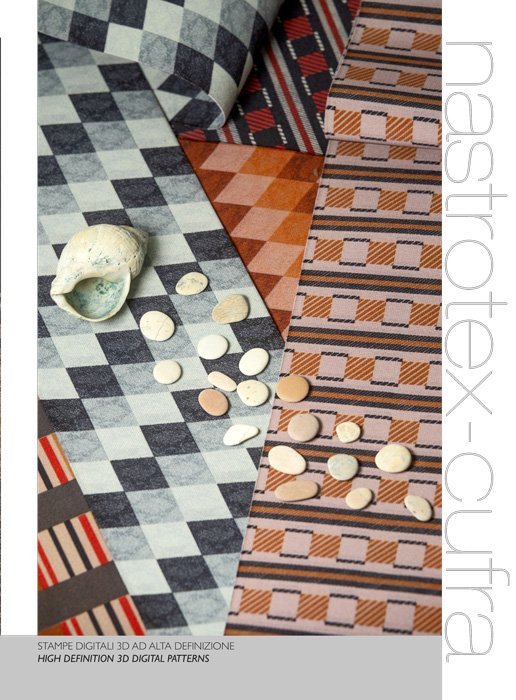

Aesthetically speaking as well as performance-wise, what are the new frontiers of your products? The new frontiers concern undoubtedly the type of raw material, that is, the yarn or the elastomer used for the production process. For example, recycled yarns, either bio-ceramic or made with graphene. Clearly enough, the technological side, related to the machinery used for the manufacturing of tapes, is equally important, as confirmed by the implementation of digital printing machine. Nowadays, customers are more and more interested in eco-friendly products.

What are your sustainable development goals? As I said previously, our products will become increasingly environmentally friendly, thanks mainly to the use of recyclable yarns. The sustainable development policy is also applied via the reduction of the machinery’s energy consumption levels, by establishing a friendlier working environment, where all the personnel can feel comfortable, and via the implementation of solar panels so as to achieve electricity self-sufficiency.

In view of the current situation, what are, in your opinion, the most suitable strategies to handle market uncertainties and the evolution of demand? Undoubtedly, market instability entails a careful corporate management, financial solidity strength allows to effectively manage such a complicated situation. Investment activities are still very much important, as they result in a remarkable price/quality ratio. Special attention should be paid to the analysis of both reference markets and competitors, striving to better understand the context in which we are operating. At the same time, one should keep a close eye on the world of fashion designers and prominent brands, in order to be, as much as possible, a step ahead of market trends.

www.nastrotex-cufra.it