Production, sales, consultancy, services and technical assistance for Haute Couture

Precursor of the modern concept of Circular Economy, Olians Plast CEO & Founder Olivieri Anselmo, expert in the field of chemistry for plastics, dedicates his thirty years long experience to the footwear sector with “new productions that necessarily require something old”. Customers can take advantage of a combination of ideas, solutions and cutting-edge technologies for the sector.

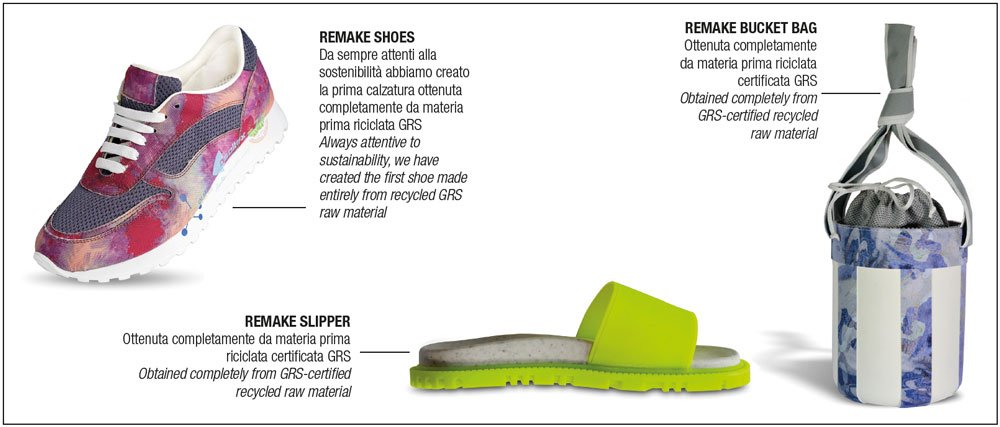

Olians Plast srl is a leading Italian company operating with thermoplastic materials for the luxury fashion sector, mainly for footwear, with a distribution of sustainable compounds and a production of a 100% green line composed of recycled materials only: from the recovery of thermoplastic materials production waste, like TPU, a new raw-second material has been created. It has physical-mechanical characteristics identical to those of a virgin material. Thus, a wide range of recycled products, called OLIFOUR, was born. They are certified GRS (Global Recycled Standard) and have a recycled raw material percentage that can reach up to 100%, always guaranteeing constant quality thanks to a specific production system in complaint with the UNI EN ISO 10667-2017 standard. Anselmo Olivieri represents many companies in the sector operating with the distribution of plastic materials in general, the sale and assistance of molding machines, coupled fabrics, coated fabrics, tips, counters and polyurethane films: Olians Plast owns even an innovative laboratory with state-of-the-art machinery to perform physical-mechanical tests aimed at evaluating the quality of the products supplied to its customers and the performance of the products obtained from them.

The innovative and modern OLIFOUR products are the flagship of this company located in Civitanova: they are produced, as mentioned above, from scraps and sprues, i.e. waste from the thermoplastic materials industry, thus creating a new raw material, with of up to 100% recycled material, that until now was considered a waste only. “Doing more and better with less” is just one of the objectives set by the UN Agenda 2030 that Olians Plast adopts, in addition to those of the Green Deal (EU). On the basis of these goals, Olians Plast has gone further by developing an LCA (Life Cycle Assessment) study from which it has stated that the environmental impact generated by OLIFOUR is significantly lower than that of virgin compounds: OLIFOUR does not affect the virgin raw materials deriving from fossil sources which could run out within a few decades. The results of this study, which analyzed the phases of procurement, production and sale of the finished product, showed that: the use of an OLIFOUR material, compared to a virgin TPU deriving from fossil sources, reduces 83,7% primary energy consumption, 81.65% carbon dioxide emissions into the atmosphere and 75% waste produced at the end of the cycle. Furthermore, Olians Plast is the first Italian company to receive the GRS (Global Recycled Standard) certification for its recycled TPUs.

OLIFOUR is just one of a variety of green practices that Olians Plast has always implemented in favor of environment and sustainability, thanks to its business philosophies that look to a more intact, long-lasting and safeguarded future: the fundamental corporate objective is to eliminate its CO2 emissions and in fact, in addition to all previous commitments, Olians Plast is building a green lung in its production plant, able to offsetting its own carbon dioxide released into the atmosphere with OLIFOUR productions.

For further information: www.oliansplast.com

Il team Olians Plast