This Ascoli Piceno company, founded in 1993, specialises in the production of compounds, a plastic material in granular form used in a large number of sectors. The challenges for the future are ready

It is a success story now reaching its 30th year that belongs to Fainplast of Ascoli Piceno, which specialises in the production of compounds, a plastic material in granular form used in a large number of sectors. The Marche company was founded in 1993 by Battista Faraotti and currently represents one of the most avant-garde realities in the plastics sector for various applications including footwear. This success is the result of constant attention to customer needs combined with a remarkable ability to develop innovative solutions, high capacity, production flexibility and quality.

Production began in Assisi, but three years later, in 1996, it was transferred to the new plant in Ascoli Piceno, in the industrial area of Campolungo, where, from an initial warehouse of 4,000 square metres, the positive response from the market imposed continuous extensions of space to increase storage and production capacity. Today the plant is a colossus that covers an area of over 85,000 square metres and consists of 8 buildings for a total of 52,000 square metres of covered facilities. With over 80 storage silos and 20 production lines, it can today claim a production capacity of over 100,000 MT/year. In the Marche headquarters we met Vladimiro Fratini, the Technical and Commercial Director, with whom we analysed the current market situation but also the challenges that await the company in 2023 and in the future.

“Turnover has always grown over the years,” Fratini confirmed, “even in 2022, despite the fact that the lack of raw materials has strongly conditioned the activities of many companies, with certain productions having stopped or at least slowed down considerably, we have continued to produce in order to guarantee supplies to customers despite the skyrocketing prices of raw materials. For 30 years I have been doing this job, it had never happened that the prices of the polymers we use increased by 100 per cent, at which point a double-digit increase in inflation was to be expected. In these early months of 2023, the market is rebalancing, even though the costs of energy and certain materials are still very high compared to traditional averages.”

Responsibility towards the environment: a very relevant subject currently on the agenda, how is this applied at Fainplast?

“We are a company that uses a lot of energy, and already in the autumn of 2019 we installed a tri-generator that not only produces electricity but also generates heat, which is made use of by converting it into cooling for our plants. We can say that we were ahead of our time when the problem of energy prices did not exist. To cover the needs of the plants we have invested in subsequently, we will install a total of about 14,000 square metres of solar panels this year, covering almost our entire premises, which will enable us to produce 2.8 Megawatts. All this will guarantee a significant autonomy, roughly half of our total energy consumption.

What are the most up-to-date figures for Fainplast?

“The market as a whole has restarted, but there are always tensions due to extra-economic factors, just to mention the most recent ones, the war in Ukraine and now the financial tensions related to banking turmoil. As far as we are concerned, at present, and this is a good sign, in the first trimester of 2023 we are at a level of sales similar to the same period of 2022, which was a very good year, and we are moderately optimistic for the continuation of the year. And if, in the meantime, signs of ease and calming on the geopolitical and financial front arrive, this could create the conditions for a boom similar to that seen in 2021, in the year following the lockdown. Conversely, it will have to be seen how the inflationary impact will affect consumption.

How is the global market reacting to the uncertainties in China?

‘Undoubtedly it is a situation that has affected the world economy a great deal, because in the past few years production had stopped, but the ports had also come to a standstill, with problems related to logistics and sky-high increases in cargo shipping costs. Now that things are slowly returning to normal, we have to see what happens with the restart, probably the market will need some more time to return to the pre-Covid situation. In the rest of the world geo-political tensions certainly do not help, for example Russia is an important country for the purchase of Italian shoes, especially those from the Marche region. This coupled with the inflationary problem we mentioned earlier, for an average consumer spending 100-200 euro more to pay the bills means perhaps foregoing the purchase of a pair of shoes. All this has led many companies, especially in 2021 and 2022, to keep their warehouses well monitored’.

Also in the area of footwear, how are you working on material development and which products in particular are you focusing on?

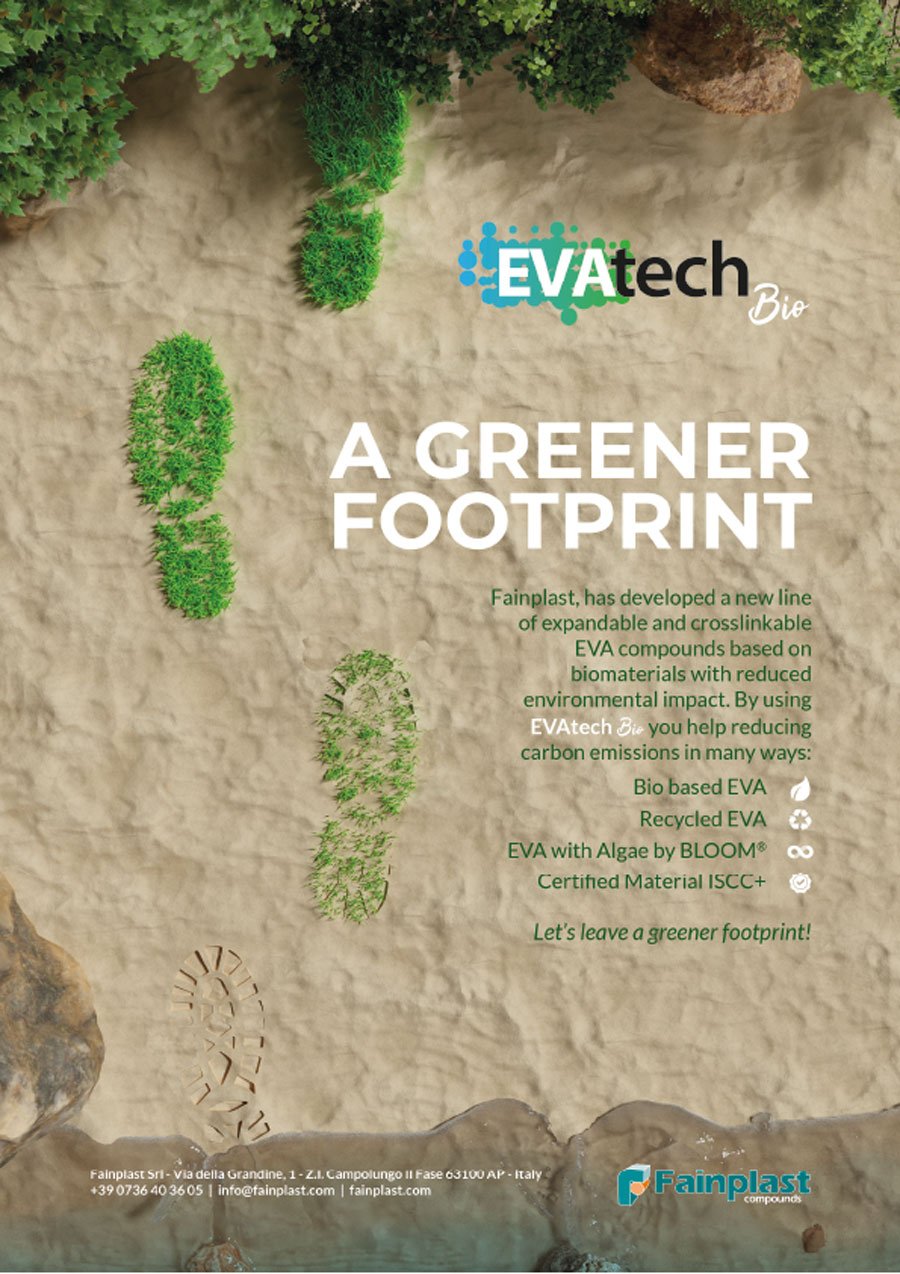

“Our prerogative is to remain focused on research and development of new products and solutions, continuing our path of renewal. Research, new technologies, and innovation are fundamental and basic elements for our company to be able to increase competitive capacity and productivity, and to meet the new needs of the sector. In the last year we have presented ourselves on the market with new sustainable compounds, namely products with varying percentages of reclaimed material and products made using renewable sources, a concrete solution to reduce environmental impact. An important innovation is a series of products containing microalgae. Here it was necessary to proceed with an in-depth study on how to use them, but the results were favourable. Thanks to the use of these biomaterials and the natural plasticity of algae, we have developed a new line that retains the main characteristics of EVAtech compounds, while preserving environmental resources and reducing the footwear industry’s emissions.

Is environmental awareness in the fashion industry a passing trend or a real need?

“A real need, especially in the footwear sector, the push towards a less harsh environmental impact is becoming more and more widespread. A demand for this comes especially from brands, which have embraced the concept of sustainability and realised the potential. At the moment this is not the case for all companies, but there is no doubt that moving in this direction will become an obligatory step for the future. A challenge that Fainplast is certainly capable of winning’.

Vladimiro Fratini