Working in the field of high-performance soles for over 50 years, Selasti S.p.A. unceasingly invests in R&D activities, carried out in its laboratories, aimed at developing cutting-edge compounds, in a countless range of colors, creating resistant, elastic E.V.A. sheets in different hardness, designs and thickness, all certified according to the standards regarding the content of toxic and bio- accumulative substances.

Thanks to a proven know-how and incessant studies, Selasti S.p.A., based in Montebonello, in the province of Florence, offers its customers a complete cycle service, from the development of the design to the choice of the compound, up to the final product. Utmost attention to quality, speed and execution precision, with a keen eye on the environment, are the primary goals of the Tuscan company and that led it achieve a leading position on the market, ranking among its customers also renowned national and international brands. “We work with compression and injection molds – Stefano Tanini Alessandri, CEO, tells us at the Selasti stand at Lineapelle – mainly within national borders, but about 40% of our production goes abroad, practically all over the world: we boast customers in Europe, the Middle East, Russia, India, even in Australia, and recently we are trying to recover America, a market that has slowed down a bit in recent years.”

According to Alessandri, the response at the fair was quite good, and the company witnessed a growing interest in eco-sustainable products which, however, are still slow to take off due to a matter of prices: “The recycled product is in great demand but little sold, few are willing to pay around 20% more than the traditional range for it. I think it will take some time before we see a real boom.” If the show went fairly well, the same cannot be said of the market trend, affected by the historical period that the world is going through: “After two years of pandemic and the related problems for which we will pay the consequences for a long time to come, the conflict Russia-Ukraine has done nothing but increase that sense of uncertainty born with Covid, upsetting and slowing down the market, which has now become enormously cautious.” Another concern, according to the company, is the immoderate increase in the prices of raw materials, which are also unavailable: “The prices of suppliers have tripled and those of energy and transport have doubled, not to mention the shortage of raw materials. It is difficult to be competitive in this context, but fortunately in the most critical periods we have been able to draw on the many materials stored in our warehouses, always stocked to face any emergency and to promptly follow up on every need of our customers. Considering that our production is completely carried out in-house, we have been able to contain logistics costs.”

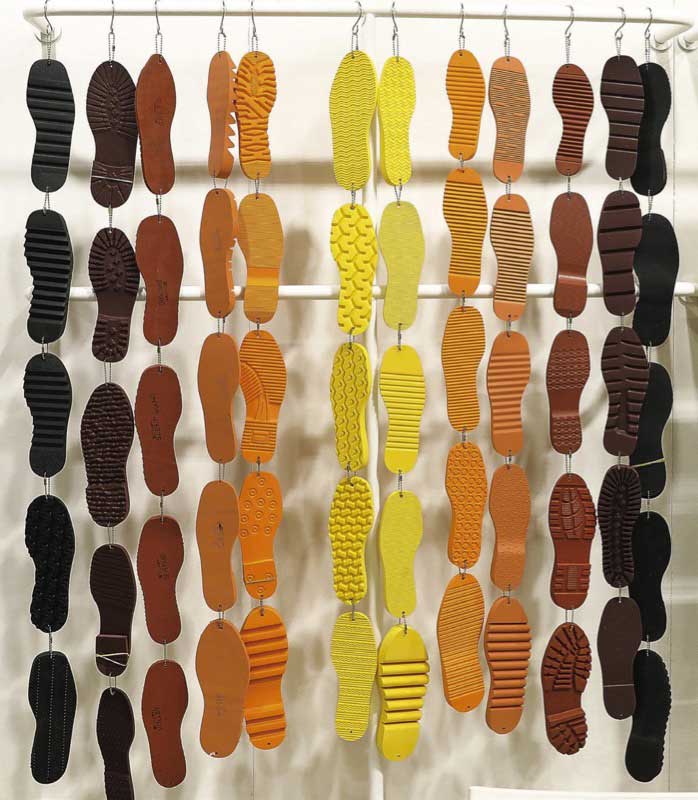

At the fair, the company’s stand was full of proposals and captivating colors: “After two years of hiatus, we are back livelier than before, – concludes Alessandri – in line with a marketing policy developed by a collaborator, who is helping us very well to give greater visibility to our brand. We are already having excellent results in this sense.”

SELASTI – www.selasti.it

Stefano Tanini Alessandri, CEO Selasti S.p.A.

Selasti’s stand and some of the products displayed