In business for over forty years, the Veneto-based company Valfussbett is a byword of quality anatomical insoles, thanks to its vast range of polyurethane insoles meant for the fashion and safety sectors. At the base of this company lie deep experience and technical skills which, combined with an unceasing commitment to the search for new production solutions and innovative materials, drive the company towards a constant growth. In addition to standard items, Valfussbett offers aims at satisfying the customers’ every need, accompanying them step by step throughout the process, from sampling to the creation of the final article, thus obtaining a 100% made in Italy, fully customized product. We talked about it with Luca Bertollo, sales manager of Valfussbett.

Valfussbett is seen as a high-end products company, so far mostly addressed to the fashion sector. But now you are also focusing on safety footwear.

Up until a couple of years ago, Valfussbett worked little in this sector as our core business was more focused on fashion; since the safety sector began to significantly grow in recent years, both in terms of figures and from a technical point of view, we started to investing heavily in this field. Our goal is that it accounts at least 30% on our turnover.

Therefore, you carried out important investments in research and development.

Investments in the world of safety have no equal in other footwear sectors. There is more courage in this area and, above all, now compared to before, when the market was dominated by low-cost safety products mostly of Asian origin, there is more attention to quality and comfort. We start from this consideration: we’re dealing with shoes that a person wears from 8 to 10 hours a day; it is essential that they are comfortable and well developed in terms of look and design. We are actually witnessing an unprecedented growth in work and safety, and Valfussbett plays a very important role in this sector, as the insole is responsible for a large part of the comfort of the shoe.

What are the most interesting products you have developed?

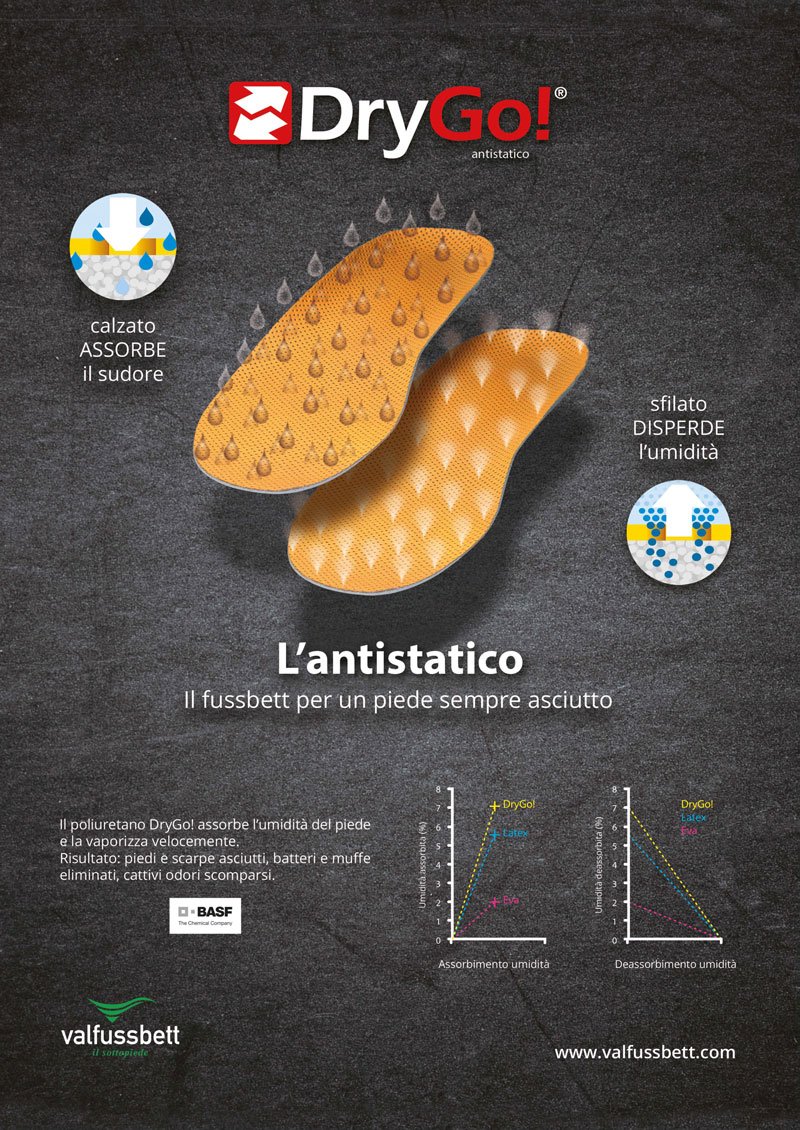

Our lively and tireless R&D team has developed several important and exclusive patents. Valair, for example, a polyurethane foam with added activated carbon that applies the comfort and elastic memory of polyurethane to an open-cell structure providing utmost breathability. We are also pushing a lot on our DryGo! patent, a polyurethane compound able to absorbing humidity and drying quickly, preventing the formation of humidity, bacteria and bad smells inside of the footwear; for the first time, we also developed this kind of fussbett boasting antistatic features. Furthermore, we conceived an article called VALIGHT. It is a very light product, the lightest extractable sole on the market (10 grams per pair), which combines lightness with the toughness of the material: you can roll them up, pull them, wash them and they weigh very little. It’s a versatile material with which it is possible to work with any thickness and which has already been praised by some loyal customers. We intend to launch VALIGHT at the next edition of Lineapelle, and the antistatic DryGo! at the A+A fair in Düsseldorf.

How do you think companies will react?

I believe that companies will be receptive because in recent years the whole safety world has revolutionized lines and performances but has not made major innovations for removable insoles: the colors and shapes change, but the same foams are always used. The opportunity to use innovative articles with different characteristics and certifications will certainly be very attractive. Italy is the pacesetter of innovation in the world of safety footwear as the major manufacturers’ clusters, who have raised the bar in terms of performance, style and price, are here. Safety footwear is evolving in an extraordinary way towards a high-quality product and people are more willing to spend more money than before in order to have a valid product from all points of view: quality, technique, design, comfort, certification and innovation. Today we pay more attention to quality than price; to collaborate with these companies you must certainly be proactive and Valfussbett carries out daily efforts in terms of research and offer. It is necessary to always be the first players among creatives and, with constant developments, to produce high-quality original innovations. The idea is to be able to supply a top-quality product with unique features, at a fair and competitive price.

La sede di Valdagno

Valentina e Lisa Guiotto

Luca Bertollo

THE ANTISTATIC INSOLE THAT ALWAYS KEEPS YOUR FEET DRY.

The first antistatic absorbent polyurethane foam, developed in collaboration with the BASF group.