Dry Go!, the successful alternative to traditional fussbett by Valfussbett, evolves into a product made of memory material that further improves the health and well-being of the foot. Try it and believe it!

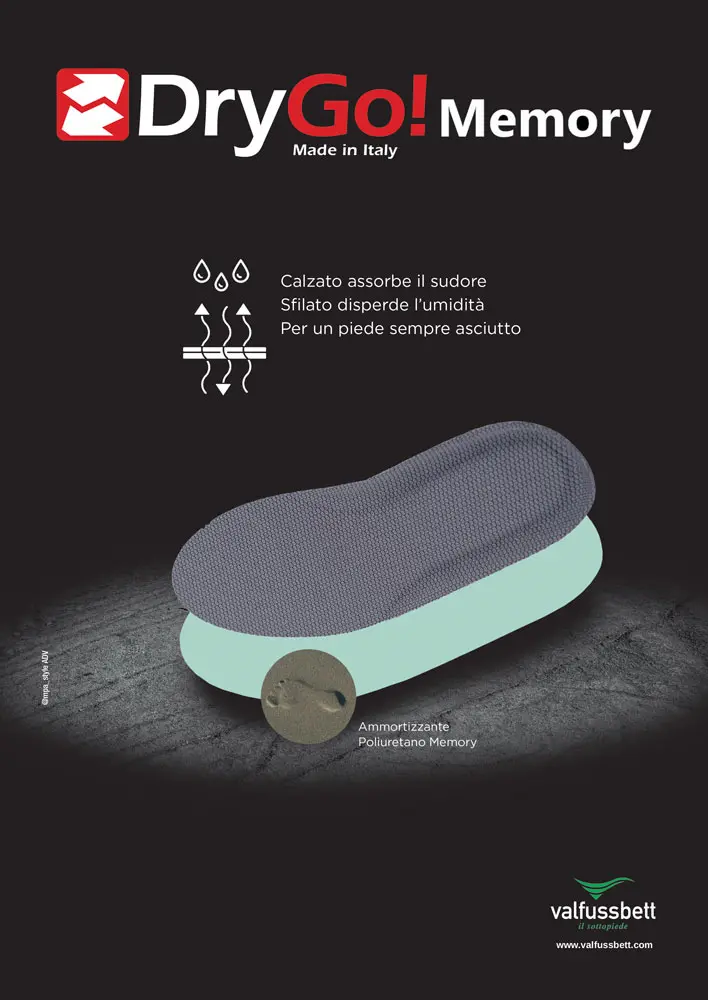

It’s called Dry Go! Memory, the new project by Valfussbett, a Veneto-based company specialized since 1981 in the production of removable insoles and items for the comfort of footwear, made with cutting-edge technologies and top-quality materials. “It is a unique product in the world, an excellence in the fussbett sector that I recommend everyone to try to experience and appreciate the immediate benefits,” enthusiastically states Dino Guiotto, president of the company. Dry Go! was introduced in 2005 as a response to the demand for innovative solutions for fussbett. Since then, it has been the flagship of Valfussbett polyurethane foams, the first insole on the market capable of absorbing and storing in its structure the humidity that is normally created inside the shoe, to then release it quickly once the product comes into contact with the air again. “Humidity is responsible for the sensation of heat in summer and cold in winter perceived by the foot inside the shoe,” explains Dino Guiotto. “The Dry Go! insole prevents sweat from stagnating, creating a climate-controlled environment that, in addition to providing a pleasant sensation of dryness and freshness, prevents the formation of mold and bacteria.” Developed in-house and made with a tailored system, Dry Go! has been perfected over the years until its recent evolution into a superior quality product, able to satisfy the ever-increasing need for comfort and well-being of footwear in all conditions of use. “In 2025, after twenty years of research and testing, at the strong request of customers we have developed a new version that combines the characteristics of the original Dry Go! with an innovative slow elastic memory polyurethane formula”, continues Dino Guiotto. “Dry Go! Memory aims to become the apotheosis of comfort: the polyurethane foam adjusts perfectly to the anatomy of the foot, offering a tailored insole that returns to its original shape once the shoe is removed.” To ensure utmost comfort it is essential to consider insole thicknesses that must be suitable to the different needs: “Our technical office is always available to customers to provide personalized advice and develop ad-hoc solutions.” Innovation while respecting the environment is also a priority for Valfussbett, ready to meet the demand for eco-sustainable products with a wide range of materials already developed: “In recent years – add the daughters Lisa and Valentina Guiotto, who respectively take care of the sales department and the purchasing office – we have invested heavily in R&D activities, developing numerous samples, however the footwear market does not yet seem ready to welcome proposals that are up to the new environmental challenges, mainly due to the higher costs to be faced. As a company we have embraced concrete measures to reduce our impact, for example through the installation of a photovoltaic system. We are also implementing a system for the correct management of waste, called ECOL360°”. Dry Go! and Dry Go! Memory are the result of years of investments in innovation, perceiving customer needs. “We have decided to reallocate the budget intended for participation in Lineapelle towards in-house investments, focused on satisfying customer requests,” concludes Dino Guiotto. “We believe it is more useful and correct to focus resources on improving our products and on technological innovation, rather than participating in trade fairs that have lost interest in recent years”.

Valfussbett president Dino Guiotto with his daughters Lisa (left) and Valentina, second generation of the family-run business