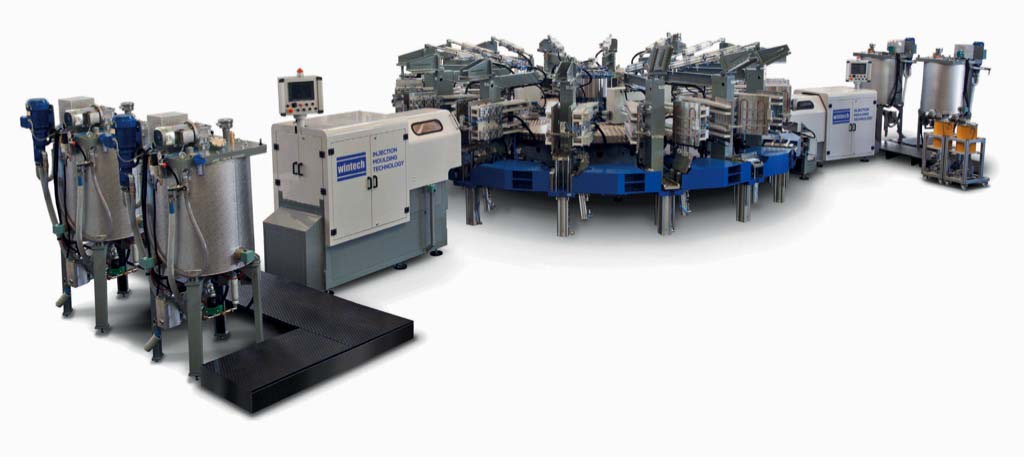

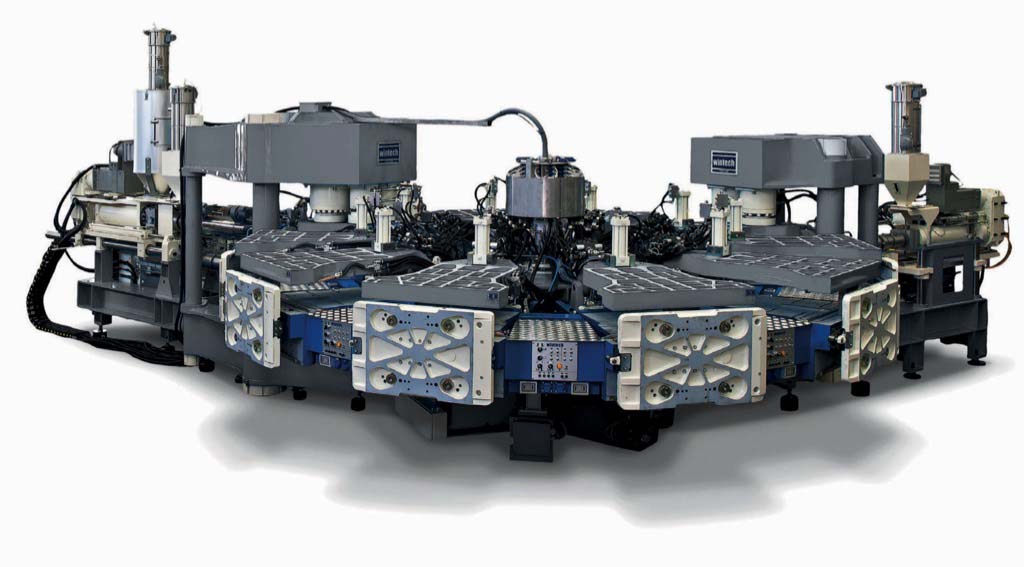

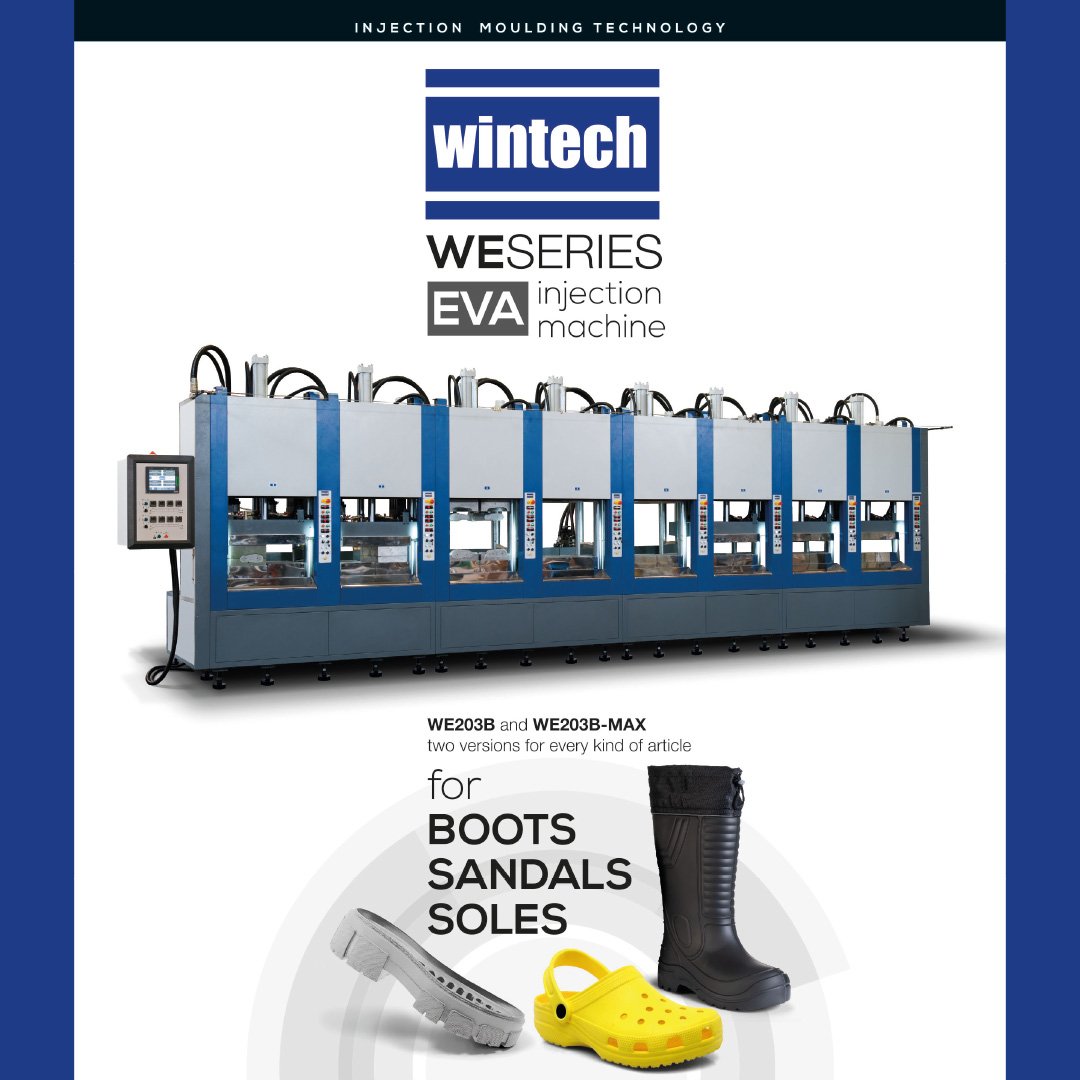

Esteemed internationally for the high quality and extreme functionality of its technical and application solutions for over twenty years, Wintech has been designing and manufacturing automatic rotary multi-station machines, static vertical press machines and linear multi-station machines with translating injectors, also for multi-material/multi-coloured productions. The machines designed and built by Wintech arise from a careful partnership attitude, based on the ‘listening & understanding’ philosophy: every customer’s request leads to the creation of perfectly customized, extremely reliable systems, designed to effectively meet current needs of efficiency and flexibility. A point of reference for manufacturers of safety footwear and boots from all over the world, the company offers a complete range of solutions for the footwear world through a wide range of injection machines for the production of boots, soles and sandals in thermoplastic materials (such as PVC/TR, SBS/SEBS and cross-linked EVA), in thermoplastic rubbers and polyurethanes, as well as machinery devised to process combined materials like TPU/PU, PU/PU, PU/ rubber for the making of safety and casual footwear. The line dedicated to the production of EVA soles, sandals, overshoes and boots is in high demand, especially in Europe, also due to the fact that, in the last two years, transport costs have risen dramatically. Another factor driving the production of EVA soles is that the finished product is so lightweight that it fully responds to the market trend for models that can be lifted with just one finger. Technology has done the rest, delivering improvements that have made EVA soles perfect for specialist footwear in segments that were previously out of reach, and that now also include that of safety. Like all its production lines, the EVA line is always attentive to the environmental impact, a real priority for Wintech: the hydromechanical system developed for injection and moulding machines saves up to 50% of electricity consumption. Wintech has adopted the same start&stop technology that is widely used in some household appliances and in cars to reduce consumption in urban traffic. The result is more sustainable production, because these machines reduce consumption and are also beneficial to the well-being of workers in the factory, since they operate quietly.