Bergi SpA, The Veneto-based company is getting ready to expand the corporate headquarters located in Arzignano, by inaugurating a new area for machine assembly and a laboratory division.Featuring more than fifty years of experience and constant investments in research, development and innovation, Bergi Tannery Machines has grown into one of the most prominent enterprises in the design, manufacturing and sales of tanning machines and equipment, achieving global success.

Mauro Bergozza, Bergi SpA

We met Mauro Bergozza: born in 1965, a true sportsman (mountain bike enthusiast and president of the Real S. Zeno Arzignano sports association, the latter comprising both the men’s football and the women’s volleyball teams) with an in-depth technical training, further supported by a long apprenticeship – he is currently at the helm of the company founded in 1965 by his late father Giovanni, a renowned and wellrespected businessman. In this interview, he described in detail the new project for the expansion of the headquarters in Arzignano, an initiative that will give to the firm the chance to provide an increasingly competitive and efficient range of services.

Can you tell us more about the construction of the new production unit? The new plant will be located right next to our current headquarters. More precisely, it’s a surface amounting to 2,600 sqm., an addition that will result in a thorough redesign of the production department as well as in a streamlined management of the corporate spaces. This facility will host the assembly and test divisions for buffing machines, dedusting machines and presses for finished leathers; we will also have at our disposal a new facility housing the sales and accounting departments, but also the corporate laboratory, thus giving us the chance to carry out in-house tests, without turning to external companies. Furthermore, we will rely on two meeting rooms, one dedicated to technical issues, the other to business ones, where we will able to hold comfortably training and refresher courses. At the same time, in the current facility, we will keep assembling the other types of machines, resulting in the doubling of the automation division, that is, Bertech.

The new plant of Bergi SpA

When are you going to inaugurate said facility? If everything goes smoothly, I hope to open it by Christmas 2019, but I am very doubtful about that. There is still a lot to do. For me, this is a very critical project, that I followed step by step and that will improve our situation in terms of available space. This addition will also lead to a marked change in attitude both on an organizational and on a production level, and it will put at our disposal an area dedicated to the training of technicians, agents and customers.

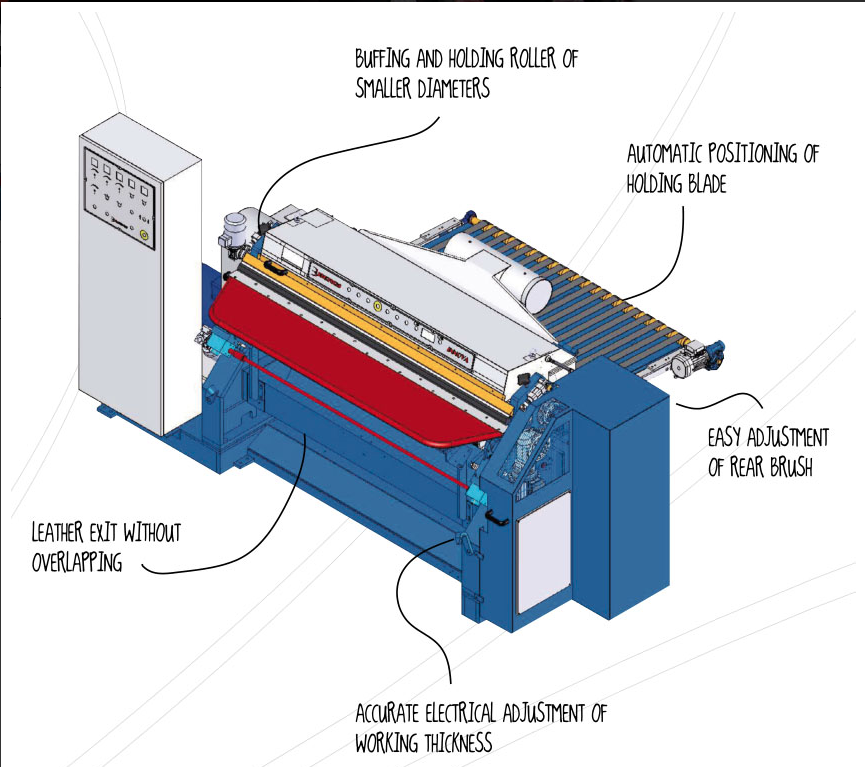

As far as machines are concerned, what developments do you have in store? At the next edition of Tanning Tech, we will showcase a new belt buffing machine equipped with spreader, perfect for processing even soft hides. Its name is “Attiva” because, due to its technical features, it can be used 24/7 without breaks. A machine designed to process vegetable tanned, oiled and waxed hides, imitation leather, synthetic materials, PU and PVC: a truly innovative model falling into step with the “Industry 4.0” parameters, provided with network connection, remote assistance, diagnostics, as well as with a useful video screen placed in front of the worker that shows the blind spot where the leather comes out, thus ensuring a constant monitoring. With this latest addition, we can put at the clientele’s disposal three different types of buffing machines, a range of cutting-edge, reliable models to be used in specific application fields. As a matter of fact, Attiva will flank Selecta and Innova: the latter has become the ideal solution for the processing of crusts, softer and small-sized hides, thanks to the reduced distance between the buffing roller and the transport conveyor. In this way, the leather comes out of the machine perfectly laid out, without wrinkles or folded edges, thus facilitating the passage through the cutting-edge dedusting machine. Our ultimate goal is to design reliable, high-performance technologies, able to guarantee the utmost production efficiency.

With regard to the market trend, what are your expectations for the upcoming future? Currently, Bergi is going through an expansion phase. However, the data collected in the last few months are not entirely encouraging, hinting at a possible stagnation. There is a growing concern for an eventual recession, in view also of the slowdown registered by the Chinese economy. Moreover, some of the protectionist policies promoted by the US President Donald Trump, including the duties on Chinese articles, are likely to affect negatively the performance of the leather sector as well as consumption rates. New opportunities might be found in Russia, especially if the sanctions were to be lifted. The world leather market has always been fluctuating; the pivotal aspect is to never lose the customers’ confidence. If there is work to do, we are always at the forefront and we never back down in case sacrifices have to be made. www.bergi.com