Gianni Maitan, Gemata

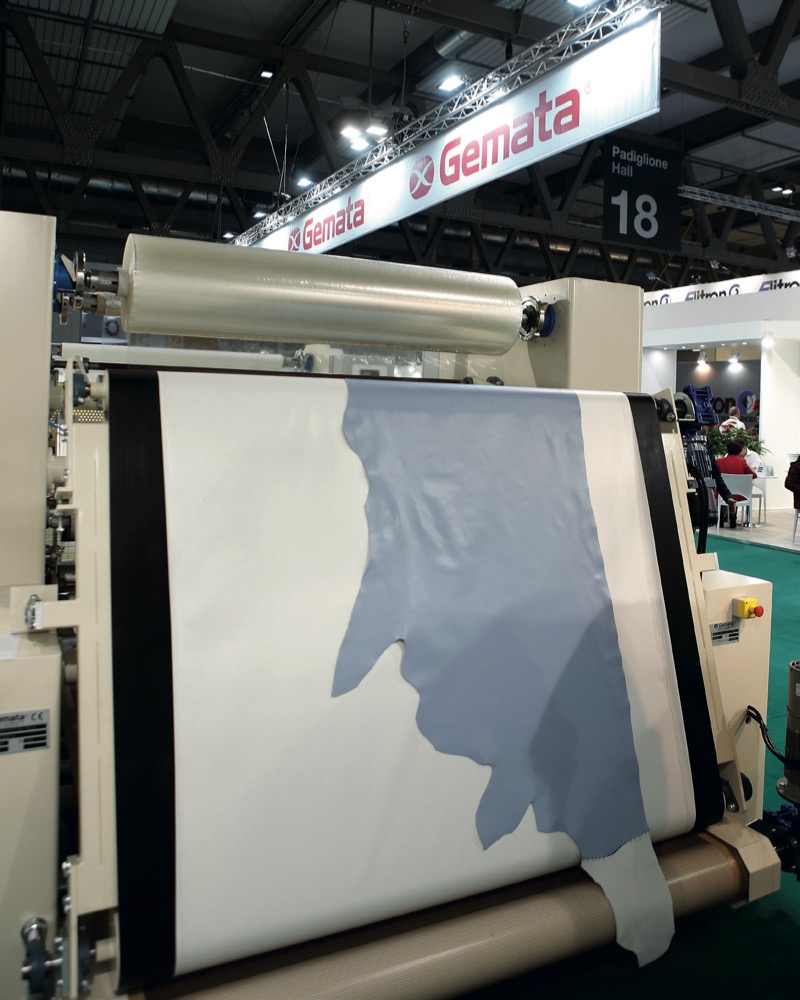

GREENFINISH, the new release paper finishing line with very low environmental impact.

World leader in the manufacturing of machines and complete lines for the finishing of leather, bonded leather, rubber, paper and imitation leather, the firm headquartered in Trissino (Vicenza province) was once again one of the undisputed protagonists at Simac Tanning Tech, the international trade show dedicated to tanning machinery and technologies held in Milan last February, since the feedback was truly positive: despite the pessimistic prospects, due to the Covid-19 outbreak that affected the attendance of professionals proceeding from China and the East, the Veneto-based enterprise registered amazing results turnout-wise.

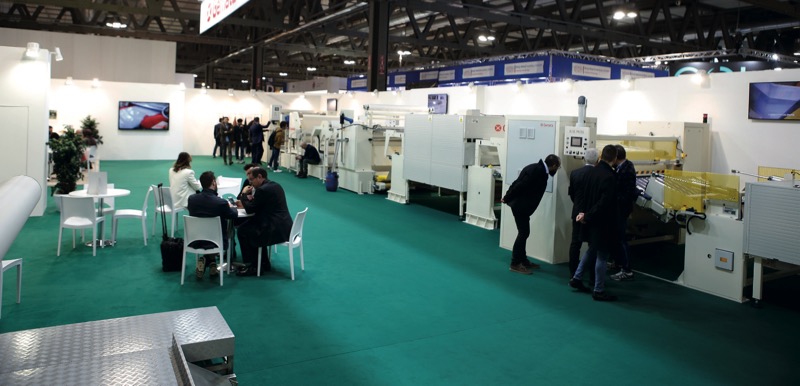

The key to this success lied in the installation, for the first time during an exhibition, of a complete finishing system, the new GREENFINISH line.

The cutting-edge finishing line GREENFINISH, featuring a low environmental impact and already used by fashion groups, ensures top-notch standards in terms of finishing quality and grain uniformity. The system is provided with a roller coating machine, designed to apply the adhesive on both buffed and full-grain leathers. “The new, low-impact line,” explained Gianni Maitan in the large corporate stand, “stands out compared to the ones sold in the past, because it is the first system to use the GREENSTAR roller machine, instead of a spray plant, for the application of the adhesive on leather, as well as to implement low-temperature infrared drying tunnels ovens that allow to finish hides with metal-free tanning techniques. We have paid close attention to sustainability, after all, this is one of Gemata’s distinctive traits. Since 1992, when I started leading this firm, I have been working side by side with the corporate technicians in order to manufacture solutions with very low environmental impact. To produce non-polluting technology has always been our starting point, not the end goal: a successful gamble, now more than ever.”

“This new finishing line,” added Maitan, “embodies Gemata’s identity: the know-how acquired in the field of roller machines’ technologies is applied to a paper release system with, thus carrying on the corporate green policy and developing a sustainability-driven project that helps decrease water and electricity consumption levels as well as markedly reduce emissions in the atmosphere. The release paper’s pattern is transferred on the film, previously coated, thanks to the pressure of the paper itself on leather, and, later, it is dried evenly on the infrared tunnels.”

Among the line’s distinctive traits, besides its strategic eco-sustainable properties, there is the plant’s small overall size (starting from 34 metres with a single coating head), compared to the previous spraying technology. Furthermore, the lack of the boiler for diathermic oil and the implementation of infrared drying tunnels lead to a marked cost reduction and to temperature control directly on the paper release’s and leather’s surface. “In addition to the low costs of the whole system,” added Maitan, “another interesting benefit lies in the competitive management costs, as three technicians are enough to run the plant. Worth mentioning also the drying ovens’ low power consumption levels, since the lamps are turned off during downtime periods.”

“One of the line’s strength,” explained Mauro Pellizzari, Sales Manager, “lies in its compact size, an interesting feature for several tanneries: a fact, not a mere marketing claim. This is the message that Gemata wanted to convey to its customers by exhibiting the plant and its true dimensions at Tanning Tech. Many were curious, some were sceptical about whether it was possible to markedly reduce the line’s length. The ideal way to show this type of plant to a potential customer would be to visit a tannery using it, but often entrepreneurs get jealous of their technology. Our challenge was to actually put on display said line: we booked one of the largest exhibition areas and we assembled the plant, so as to give to everyone the chance to see the project first-hand. It was a significant investment, but, in my opinion we have succeeded in arousing a lot of interest: we have exhibited a line that is ready to be installed in a tannery, we grasped the customers’ wishes and we have turned them into reality, as we usually do.”

With the official launch of GREENFINISH and GREENFINISH SHORT (20 metre long, with an autonomy of 1000 metre of paper release and a production speed amounting to 6/7 metre per minute, designed for small-sized tanneries and that finish small batches of hides), Gemata confirms to be the leader in the tanning sector on a global scale, “also by virtue,” stated Maitan, “of eco-friendly and technical innovations as well as of those concerning size optimization: a result achieved thanks to the commitment of the whole team. Ours is a company that can rely on highly qualified human resources and on valuable partnerships with the customers: we collaborate constantly with them in order to find cutting-edge solutions and to customize technologies according to their requirements. This is the strength that helps us achieve new goals and look forward to the future.”