GOMMUS has launched in 2019 a programme aimed at the recycling and enhancement of processing waste, as well as their re-use in the production cycle.

Constantly committed to the research of low-impact materials and manufacturing techniques, Gommus has kicked off in 2019 a new project that aimed at the recycling and enhancement of a substantial share of processing waste. Previously, rubber residues were usually sent to landfills, as the vulcanization process was deemed irreversible and, therefore, there was no way to reintroduce them in the production cycle.

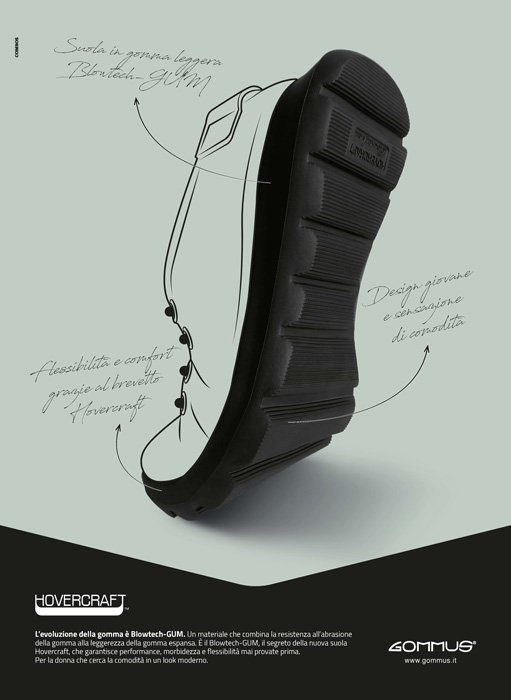

Now, the Marche-based company, specialized in the manufacturing of soles, is able to reverse said process, thus turning scraps into a brand-new raw material – recycled and certified, it can even account up to 30% of the soles’ structure, without going to detriment of either the performance levels or of the product characteristics (lightness, comfort, range of colours). Boundless versatility both in terms of style and design. Thanks to this innovation, an increasingly large share of residues is recovered, processed and then re-introduced in the production cycle, thus succeeding in extending rubber’s life cycle and resulting in a marked reduction in the amount of waste generated.

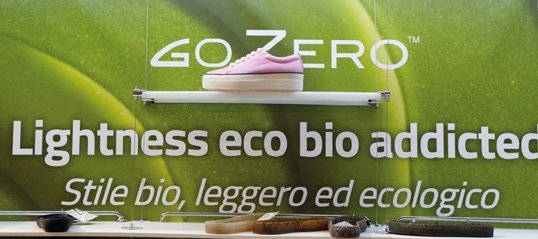

Undoubtedly, this is a strategic value for the degradable, eco-friendly soles Go!Zero, now available in recycled rubber as well. Worth mentioning the fact that Go!Zero is the innovative compound developed by Gommus, able to decompose in a very short time: as a matter of fact, researches have highlighted a compost degradability rate amounting to 34.53% in 180 days, in compliance with the UNI EN ISO 14855 protocol, in addition to the complete absence of phytotoxicity in the degraded material. The trend analysis, developed on the basis of real data, underlines another interesting information, that is, the chance to reach, in theory, full degradability (100%) in approximately 502 days.

Production waste recovery is now acknowledged as an integral part of the sustainability-oriented philosophy fostered by Gommus over the years: an ongoing commitment, as confirmed by the achievement of the UNI EN ISO 14001 certification, by the steady use of renewable energy thanks to the solar panels installed in 2009, as well as by the implementation of the cogeneration plant in 2017.

www.gommus.it