Unceasing quality and excellent technical/mechanical properties define the products made by Inline, intended for all types of footwear

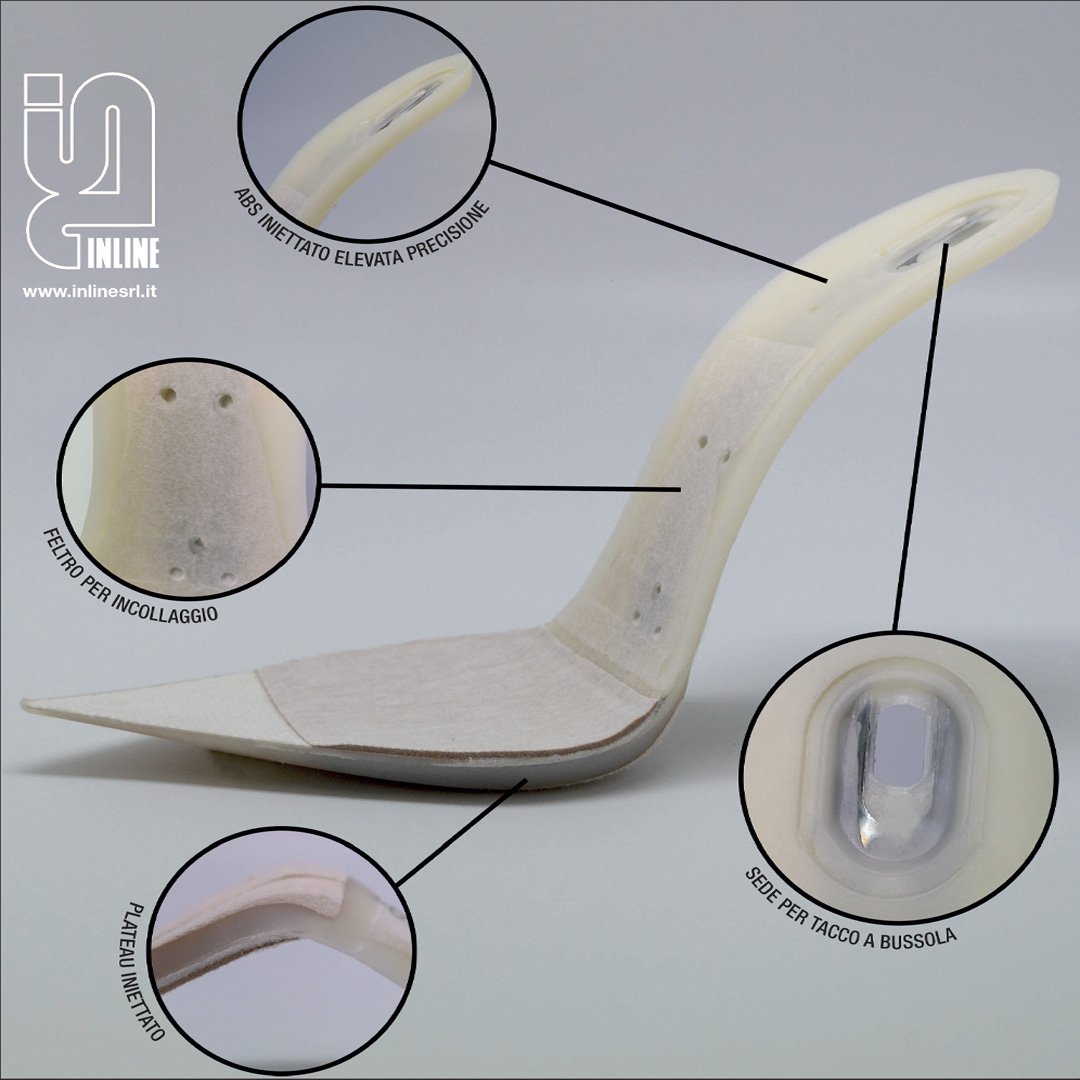

The company Inline, among Italian the excellences in the footwear components sector, is back to Lineapelle with a rich range of assembly insoles that express the company’s commitment to constant research and experimentation with new materials and cutting-edge technologies. “Unlike traditional assembly insoles – says Riccardo Cognigni – the Inline insoles are made through the injection molding technique of specific blends of plastic polymers, using molds designed specifically based on the customer’s needs for perfect adherence to the shape of the shoe. Process precision and resistance to breakage are the main features of this item, boasting high standards of quality, safety and comfort and therefore particularly suitable for the application on high heel shoes.” However, the use of the insoles produced by the Marche-based company ranges from elegant footwear to the technical sector, from sneakers to slippers. The entire production cycle, from prototyping to the finished article, takes place in-house, to offer the customer a personalized service that guarantees full satisfaction.

The company is aware of the sustainable production responsibility. From the first processing stages to packaging, Inline relies on a high percentage of secondary raw materials (some insoles are made of 100% recycled material), in order to guarantee the lowest possible environmental impact.

Riccardo Cognigni at the Inline stand at Lineapelle

Monobloc sole and insole with customized fabric inserted directly inside the mold

Injected assembly insole with plastic insert able to replace the steel plate