Main Group Technologies is a historical brand boasting a long tradition, a history of technology and innovation. In over 80 years of business, Main Group has represented the reference technology for injection molding of the main productions in the footwear sector.

The Venetian group, based in Santa Maria di Sala, has served more than 16,000 customers throughout the world with its machines, to which it still provides assistance and spare parts.

The strengths of Main Group Technologies are: a wide acknowledge in technology, customer assistance, added value machines, a low-cost production and attention to the human being and the environment.

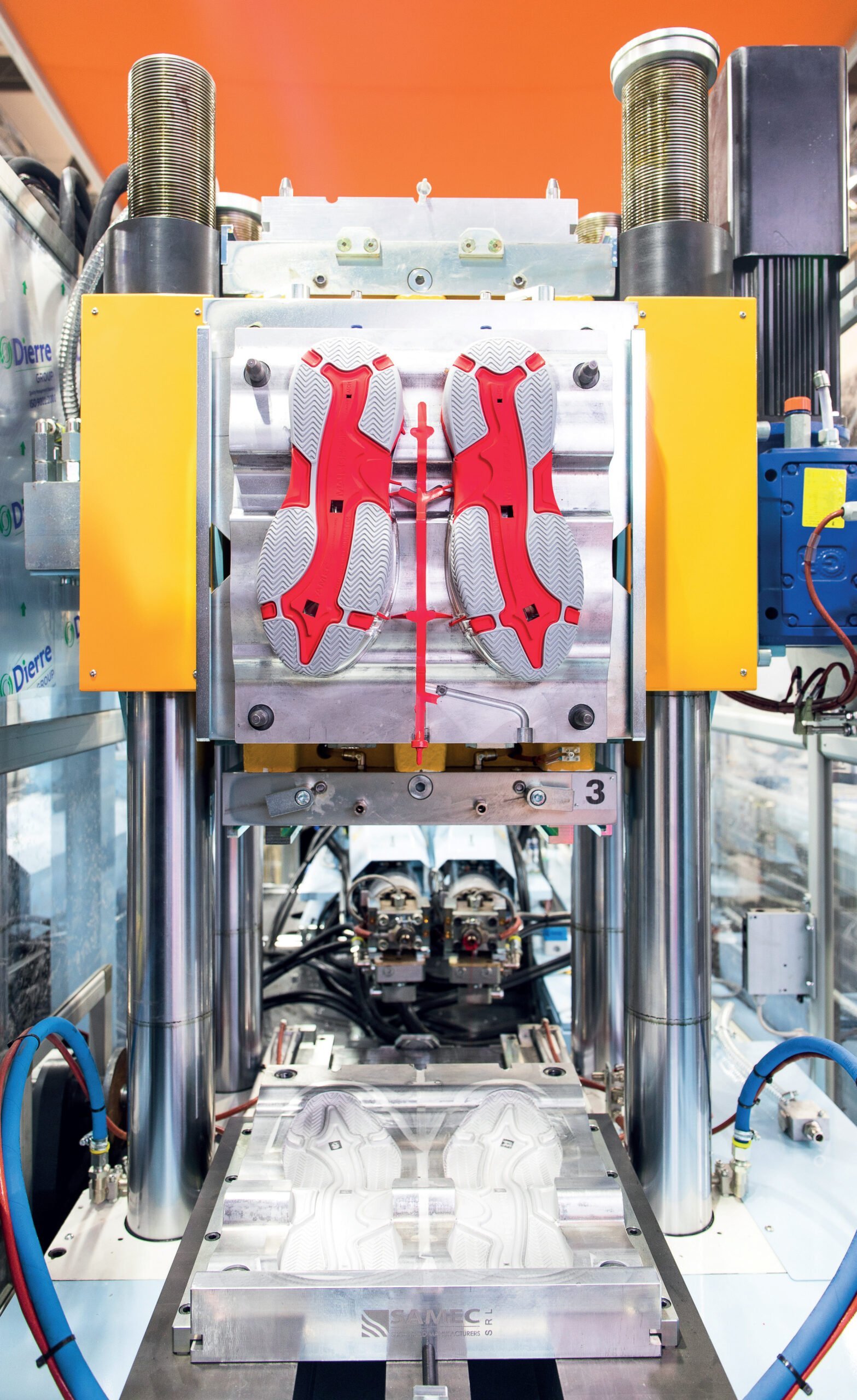

Main Group Technologies’ machines are robust and reliable, standing out among the most advanced technologies for footwear and safety boots in Polyurethane, TPU, Polyurethane + TPU and rubber. The wide company offer includes static machines with 2 or more working stations (easy to manage and ensuring high productivity), rotary machines for boots featuring mold holders with fast junctions and openable door, the system of EVA injection, compared to traditional thermo-molding; in the rubber field, the injection-casting in open/closed mold; in the polyurethane field, the injection of TPU + PU with integrated cycle on the same machine.

Thanks to the use of these machines, customers achieve significant improvements in terms of time savings and costs reduction.

“We are satisfied with this edition of Simac; – says Mariano Bonato, Main Group Technologies’ CEO – we have collected several contacts that we’re going to cultivate in the following months. As for the company, 2018 closed well and we are confident for 2019 as well.”

After joining new industrial and financial forces, Main Group Technologies has evolved over the years through modern industrialization criteria. A new plant of Main Group Technologies was built some years ago: this building boasts a captivating design and hosts the bureau, management, sales, marketing, purchasing, production departments and the design office.

An indoor area of 4000sqm is entirely dedicated to assembly, building and testing of the machines. The production capacity of the Main Group Technologies plant is optimized to quickly meet the demands of each type of customer.

A part of the plant is assigned to the Research & Development Lab, where lies the true heart of the company. Each customer project is followed with design wisdom and production optimization. The result meets the market needs and the production updates, as Main Group’s machines are always technologically advanced.

A 4000sqm warehouse stores all the production components and spare parts, whose arrangement and handling are quick and functional, thanks also to a new management software system.

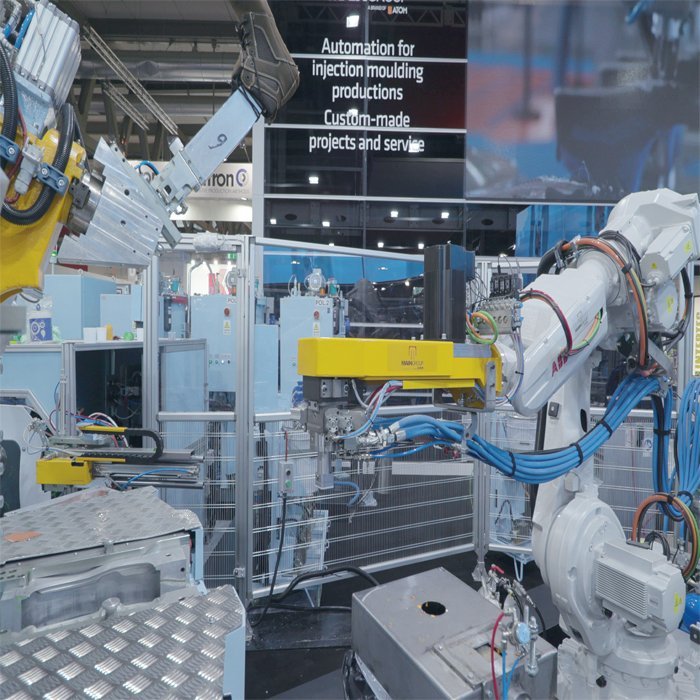

Main Group Technologies displays its machines at the most important fairs in the world, from Europe to the Far East.

www.maingroup.com