Main Group Technologies, increasingly high performances that can fulfill all kinds of production needs. This is the flagship quality of the machines designed by the Veneto-based company for the footwear sector. Technology at the service of productivity. This is the distinctive trait of the innovation developed by Main Group Technologies. As a matter of fact, the Veneto-based enterprise, specialized in the design and manufacturing of injection moulding machines for the footwear industry, keeps on implementing and improving, thanks to the support and commitment of the in-house R&D department, new tools and applications aimed at upgrading plants’ effectiveness and quality standards.

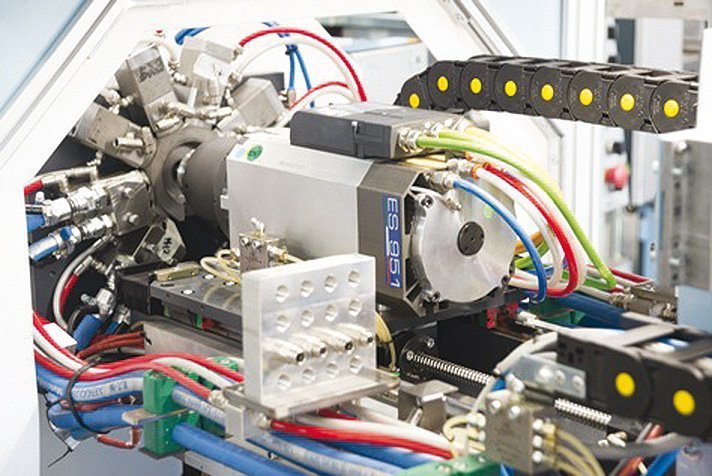

Twin Injector, the patented system that can be implemented on direct injection machinery such as the Pragma range.

This is the case of the patented system Twin Injector, a true breakthrough concerning the efficiency and productivity of the cutting- edge Pragma machinery, conceived for the direct injection of soles in combined 232 materials. The introduction of two injection heads – designed to take turns at working at high speed, in perfect coordination with the machine’s rotation schedules – allows a streamlined management of several operations such as the change of colour or of the PU density. Therefore, both processes can be carried out without interrupting the production cycle. The Twin Injector system results in a 15% increase of the OEE rate (Overall Equipment Effectiveness, that is, one of the most important parameters used to assess production effectiveness), thus leading to a marked decrease in costs and time. www.maingroup.com

Main Group is a longstanding brand bringing with it an extraordinary wealth of technology and innovation. In its 80 years of activity Main Group has set the technological benchmark for injection moulding of the main productions in the footwear field.

To mention but a few examples:

- static machines with 2 or more stations, simple to manage and offering high production rates

- rotary machines for boots, with mould-holder featuring fast couplings and opening male holding plate

- EVA injection system, as opposed to traditional thermoforming

- rubber, injecting-pouring into open/closed mould

- polyurethane, injection of TPU+PU with integrated cycle on the same machine

All this doesn’t happen overnight: bearing testimony are the 16,000-plus customers all around the globe with machines that in many cases have been working for years, and who are still receiving the Company’s support for assistance and spare parts. Main Group brand presents to the market with a wealth of machines and is bolstered by new technological and production resources, which enable significant improvements on an industrial level. Main Group Technologies is a new dynamic company borning by an industrial and financial pool, whose organization embraces rules of modern industrialization. Through a combination of design rationality and production optimization, the company meets the today market demands both on economical aspect and upgrade production, offering improved and up-to-date machines.