In the limelight at Lineapelle, the excellent results achieved by Manifattura Pri.Ma.Tex in technical fabrics for safety: top effectiveness, quality and performance

Developing innovative technical fabrics with the ability to improve every day in order to compete in the market. This is the mission of Manifattura Pri.Ma.Tex, a company based in Prato specializing in the production of high-performance and eco-sustainable items for PPE destined for the industrial and building sectors, fire brigades and police forces, automotive, extreme sports, and forestry operators since 1997.

“Our research,” say Rudy Priami, General Manager, and Mariangela Fanfani, Sales Department, “is aimed at developing quality products while paying the utmost attention to the final aesthetics of the fabric. We always try to raise the safety levels required by current regulations, while keeping the comfort of the end user as our focus. The articles presented in the new 2024-2025 collection have a tear resistance of between 500 and 600 newtons, values that are up to ten times higher than the current standard. The abrasion resistance tested according to UNI EN 388:2019 6.1, using the Martindale method, exceeded ten thousand cycles compared to the maximum eight thousand required by the standard. With reference to the textile anti-puncture foil EN 22568/4:2021 PS,3mm conical tip nail, we offer several products, with various weights, thicknesses ranging from 3.6mm to 4.2mm, performances and prices, guaranteeing a unique flexibility and lightness, with an excellent workability compared to the materials already existing on the market.

A fully Global Recycle Standard certified company, Manifattura Pri.Ma.Tex also presented at the fair the GRS-certified anti-perforation textile foil type PS, obtained from recycled materials.

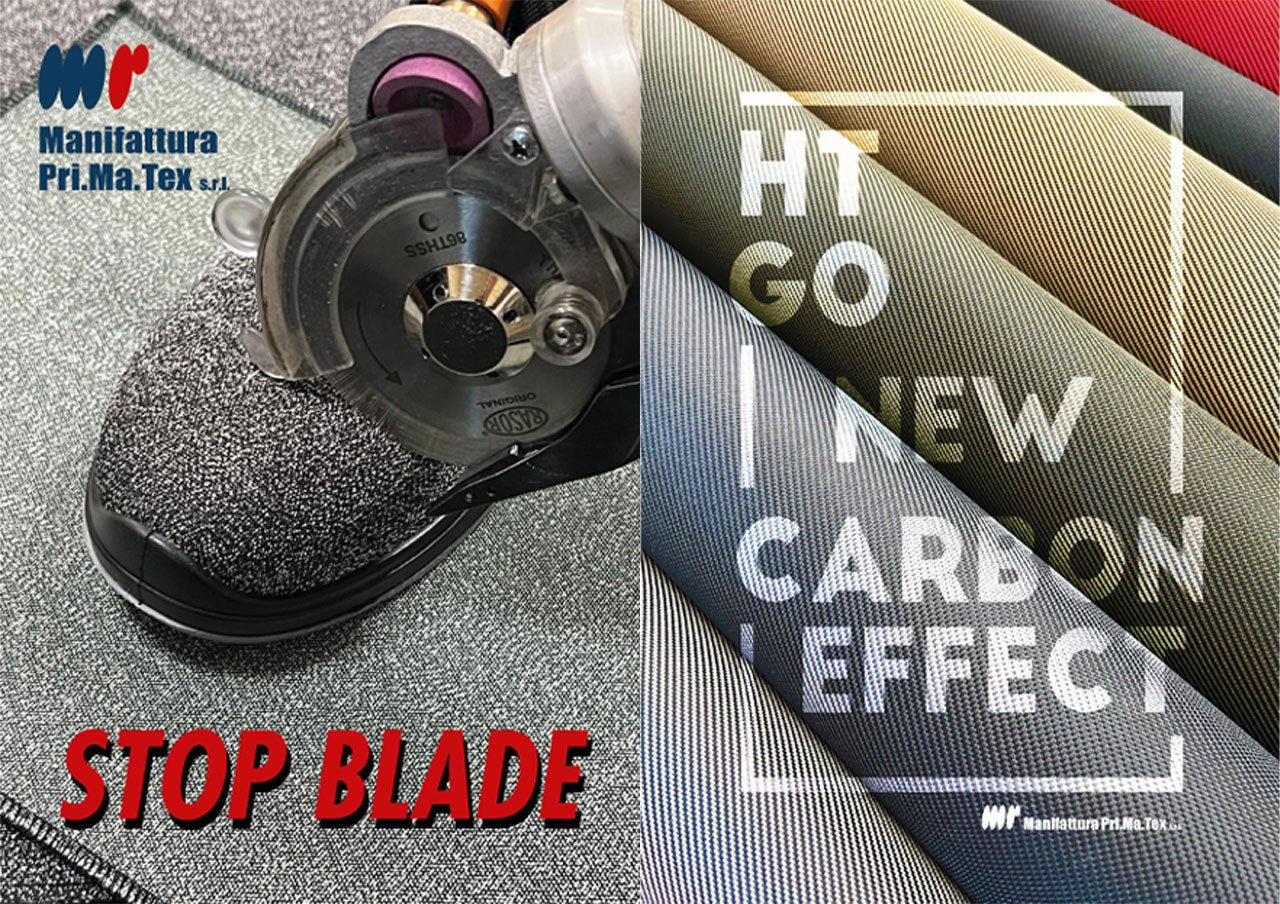

“The philosophy of the company is to offer a highly qualified product that is resistant to wear, abrasion, tearing and cutting: the main attraction in this respect is the new Stop Blade upper technology, a blade cut-resistant fabric that is resistant even to chisel cuts or any work accessory,” Rudi Priami shows us. Presented at the latest edition of Lineapelle, it comes with a QR Code tag through which the end consumer can watch the demonstrations by the workers. “This is a cut-resistant item with very high tear resistance, suitable not only for a work shoe, but also for a professional sports shoe, e.g. mountaineering or hunting shoes. As a matter of fact, it does not scratch or cut with the pressure of the blade, the fibers remain intact and do not split as happens with other fabrics. It is at the same time breathable, water-repellent and has a wide range of colours. The fabric is made of 100% Dyneema, a synthetic fiber used especially for sports and professional applications, high resistance to twisting and bending stresses.

Although it is a ‘standstill’ period with few new offerings on the market, Manifattura Pri.Ma.Tex does not stop investing in research, but intensifies the development of new high-tech textile solutions technology to ensure greater protection and safety.

General manager Rudy Priami showing the cut resistance of the Stop Blade technical upper fabric at Lineapelle

The innovations for uppers presented at the fair