During the lockdown period, Officine di Cartigliano launched on the market a Vacuum dryer and a system that provides a “new heart” to used machines, designed to guarantee top-notch performances

During the Coronavirus emergency, in such a complicated situation for the whole world economy-wise, OFFICINE DI CARTIGLIANO managed to once again amaze everyone, standing out, both in Italy and abroad, for the launch of new ideas and products. More specifically, it is a cutting-edge system that allows to give a new heart, #BLACKHEART, to existing machines.

What does this innovation entail? With #BLACKHEART, top-notch performances can be achieved even with used machines, without replacing the whole plant. Another achievement for this prominent firm, at the forefront in the field of R&D activities, able to keep ahead of times and to find practical and suitable solutions in this peculiar situation.

OFFICINE DI CARTIGLIANO is the world leader in the design and manufacturing of machines for the tanning sector, especially of drying and conditioning units, staking machines, radio frequency plants for the finishing phase and for crusts. Its range of solutions comprises also polymers drying and regradation systems, machines for the food industry conceived for the pasteurization and sterilization of liquid and semi-liquid food, and, last but not least, technologies for the environmental sector, such as dryers devised for both industrial and civil sludge. The Veneto-based enterprise, led by the president Antonio Polato, was established in 1961: in a few months, it will celebrate its 60th anniversary, a long adventure characterized by a steady growth, as confirmed by the partnerships with customers based worldwide, by the filing of countless patents, the latter acknowledged as a priceless asset in terms of innovation and research.

Antonio Polato Presidente Officine di Cartigliano

We met Antonio Polato in late July in order to assess the situation, concerning both corporate activities and the market trend.

As far as OFFICINE DI CARTIGLIANO is concerned, how did you spend the lockdown period? It was a complicated period for everyone, no use hiding the truth. We overcame those difficulties by launching some innovations and by setting the bar high once again. Those who know us, are well aware of the fact that we invest significant resources in research activities, carried on during the spring months, when we had the time to deal properly and thoroughly with several topics, working to fully understand the customers’ demands in this unique, unpredictable moment.

Market-wise, what did you do when activities resumed in May? Based on the assumption that several companies had to put on hold their businesses, we tried to plan out discounts and special packages, especially when it comes to spare parts. Another equally successful strategy concerned the sale of machines with peculiar disinvestment initiatives (for example, a payment scheduled twenty-three months after the delivery, thanks to the Credit Export Agency’s support), thus providing both technological and financial solutions. As a matter of fact, in this way, we have helped customers get ready to resume their activities once the economic situation will improve. This choice has led us to handle, during summer, several orders, at a time when it is really complicated to sell something and in which enterprises have no interest whatsoever in investing resources in machinery and plants.

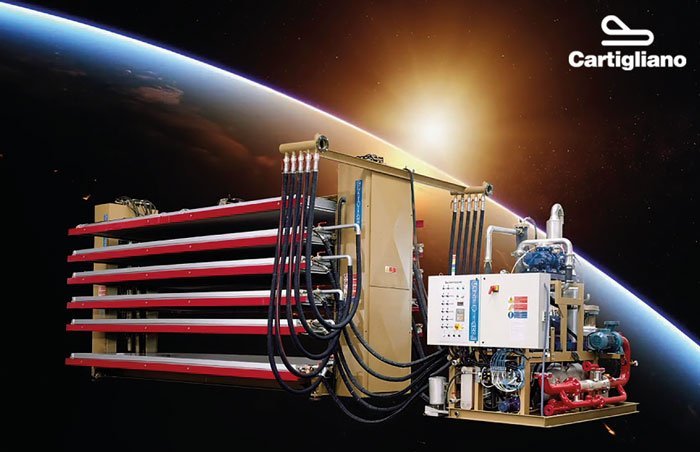

What can you tell us about Black Heart, the innovation launched in 2020? It is an unprecedented solution, we believe it will be highly successful in such a difficult period economy-wise. Nobody knows our machines, their technology, their performances and potential, current and future ones, better than us. We guarantee interesting benefits thanks to a “black heart”, able to give new life, assembled by the same people who designed and produced the plant itself. Black Heart is a system that can be implemented on the Cartigliano’s Vacuum Dryers already purchased by our customers, boosting their performance and providing the old models with a new heart. In this way, we ensure first-rate performance standards: leather temperature at 25°C, high productivity, zero environmental impact, remarkable yield and Plug&Play, that is, no installation required. In a nutshell, three key concepts: saving, simplification and new life to business.

What other patented machines do you plan to launch this year? We will soon launch a true innovation concerning a new drying plant, used in different ways in the tanning sector as well as suitable for the pharmaceuticalmedical industry. Said machine can operate in conditions of absolute vacuum; after that, it is the turn of radio-frequencies for the heating process. Another cutting-edge technology has been designed for polymers drying, namely, the first solid-state radio-frequency generator: an ambitious, one-of-a-kind project, in which we have invested plenty of human and economic resources.

In your opinion, what are the international markets’ main critical issues? Exports account for 85% of our revenues. Therefore, it is only logical that the global deadlock situation will end up affecting us. We have machines yet to be tested in China. However, during the lockdown, we powered up a radio-frequency plant sold in Korea, by communicating remotely with the customer: a technicaloperational chat with the other side of the world! Our team of engineers developed a new way to provide the required instructions and to start up the machines. Recently, I went to Mexico, a market really tied to the automotive sector: in July, their work rate reached approximately 65-70% compared to the average of the last few years. A fairly positive trend.

And from a commercial point of view? We are about to finish the development of an online platform, that allows to display and share with our customers the tests carried out daily in our R&D department. This will give us the chance to make up for current travel restrictions. Foreign customers that can’t take part in person in the tests with their products, will experience a virtual visit with our area managers. An amazing tool for the future as well, in case the customer can’t travel to our headquarters: to help them taste the “Cartigliano family feeling” online is the challenge awaiting us for months to come.

What about the domestic market’s situation? We have received a few orders from Tuscany, where we attended as exhibitors the ProssimaPelle event, held in mid-July in Santa Croce sull’Arno. The feeling is that, as weeks go by since the beginning of summer, things are starting to move, especially in SMEs, while big brands have been affected deeply.

What are your main concerns right now? The whole supply chain’s ability to bear the strain. We are witnessing a grave crisis for subcontractors, that might end up hindering large-sized companies such as ours. Another issues revolves around raw materials supply: for example, it takes to much time to purchase stainless-steel sheets, a problem that might slow down production. Another concern of mine regards the travels abroad of fitters, forced to undergo quarantine once they reach that Country and when they come back.

What are your short- and mid-term prospects? I am a confident person, a trait I do not want to give up on even now. We send out positive messages, because we believe that this situation is going to improve. Economy-wise, in the second half of 2020, there will be a recovery, though a slow one. It will take some time to get back to pre-Covid19 levels. This pandemic, an unprecedented occurrence in terms of expanse and scale, is a true epochal event. The definitive solution lies in the development of a vaccine, scientists worldwide are working hard to achieve that goal. www.cartigliano.com