Established by professionals with more than thirty years of experience in the business, SPRAYTECH deals with the design and manufacturing of systems and accessories for industrial painting; at the same time, it is an internationally renowned enterprise in the field of cutting-edge automations and special plants as well, thus providing the clientele with innovative solutions.

Established by professionals with more than thirty years of experience in the business, SPRAYTECH deals with the design and manufacturing of systems and accessories for industrial painting; at the same time, it is an internationally renowned enterprise in the field of cutting-edge automations and special plants as well, thus providing the clientele with innovative solutions.

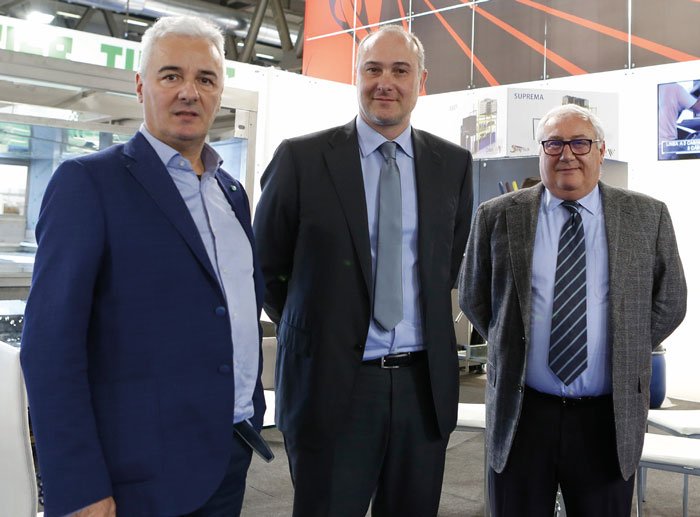

Mauro Golin, business partner, Marco Zampieri, the general director, and Claudio Carmagnola, Sales Department

An ample selection of said technologies, including several patents filed by the company headquartered in Lonigo (Vicenza province), was exhibited at the latest edition of Tanning Tech, held last February at the Rho-Fieramilano fairgrounds. “Patents are one of the most valuable assets for any firm,” explained Mauro Golin and Marco Zampieri, respectively SPRAYTECH’s business partner and general director, “an added value that actively contributes to the corporate success. Our enterprise can rely on a significant and interesting array of patents, a factor that helps us keep up our competitiveness on the market. Furthermore, the constant commitment to research results in the steady upgrading of our machinery and plants, as in the case, for example, the automated colour change system STS (acronym of Spraytech Time Saver, Ed.).

If applied to a painting plant, it guarantees excellent results in terms of time saving, resulting in a marked increase in productivity, so that the customer can amortize it in three months on average. This is possible because the STS system allows to carry out the washing as well as the colour change operations during the normal production, not in between batches, as it usually happens.” At the Tanning Tech trade show, SPRAYTECH showcased other state-of-the-art technologies, like the LES device – Leonardo Energy Saving -, RINT flow regulators, the new rotary distributors, the Waterflow spray booth, EPS Leonardo and the FLY rotary carousel. “During the exhibition,” stated Golin and Zampieri, “we have displayed the innovative spray booth Waterflow. Entirely made in stainless steel, it has been designed with three layers of water in order to get a cascade effect that markedly reduces the amount of polluting agents released in the atmosphere.

The special attention paid to environmental safeguard issues is one of the priorities pursued by SPRAYTECH, acknowledged as an added value to its technologies, together with the decrease in energy costs and the improvement of production efficiency.” “Our machines,” added Golin and Zampieri, “are designed to be customized, so as to promptly meet the specific requests of each customers. If the global market requires our applications, we are able to ensure the utmost ease of use by supplying control displays that can be used in all languages. This internationalization-oriented attitude has played a key role in markedly increasing our export share, currently accounting for the 60% of the corporate turnover: even though our products have been chosen by the majority of the companies based in the Arzignano’s and Chiampo’s districts, as well as by the most prominent multinational corporations all over the world, we are gearing up to become the perfect partner to tanneries worldwide.” www.spraytech.it