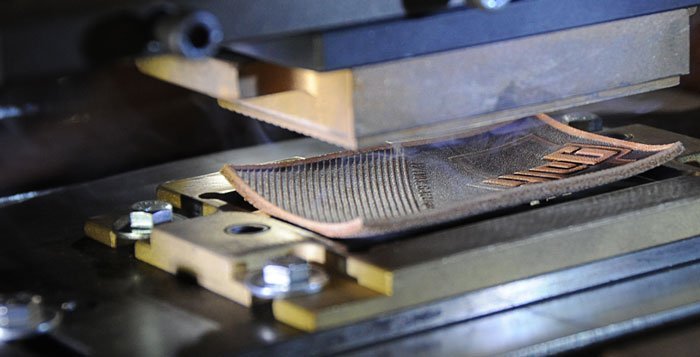

Galli Spa, company was established by Emilio Galli who, right from the beginning, chose to focus on technological innovation – a story started in 1979 and deeply tied to Vigevano, Pavia province, acknowledged as one of Italy’s most prominent clusters when it comes to the production of quality accessories and footwear. After more than forty years, Galli Spa has grown into a leading company in the field of the design and manufacturing of leatherware machinery. The innovation-driven attitude, combined with a long-standing experience, have helped the firm turn into a global benchmark in terms of quality and technical precision. Galli Spa is specialized in the development and production of a wide range of plants and work lines for leather goods: punching machines, embossing machines, stapling machines, combining machines, strip-cutter machines, trimming machines, milling machines, lapping machines, brushing machines, colouring machines, glazing machines, ovens, loading/unloading robots, and much more.

Carlo Galli, sales manager Galli Spa

“At the latest edition of Simac Tanning Tech, we have showcased an upgrade of our leatherware machinery, featuring new functions concerning leather cutting and gluing,” explained Carlo Galli, Galli Spa’s Sales Manager. “Our customers are praising the brand-new, fully robotized systems for leather processing.” Now, the corporate product portfolio comprises more than sixty models, all designed to guarantee an increase in quality standards and in production efficiency.

Galli Spa distributes its technologies worldwide, especially in countries where high-end and luxury leather goods and footwear are manufactured. One of Galli’s main strengths lies in the technical service. A dedicated team manages the design phase, focused on the conception and development of new technical solutions and innovations according to the customer’s specific needs.

The steady progress and constant experimentation, concerning both the end article and the 3D modelling via PC, result in top-notch, cutting-edge machinery, even from an economic point of view. Thanks to the implementation of CAD design and of advanced CAM production systems, the technologies made by Galli Spa are designed and manufactured in order to ensure the utmost reliability and ease of use. The whole design phase is carefully carried out with 3D modelling systems.

“2018 turned out to be a positive year for us,” added Carlo Galli, “and 2019 started off with new orders. We keep investing resources in the development of new machines and functions.” Another flagship of the company headquartered in Vigevano lies in the customer care service, both pre- and post-sales. Galli Spa’s assistance centre operates worldwide so as to solve the customers’ issues and provide a first-rate service.

As a matter of fact, the company pays close attention to two pivotal aspects with the aim to branch out its market position: continuous assistance/ upgrading of the corporate technologies, thus ensuring product continuity. The steady contact with designers, pattern-makers and industry specialists has actively contributed to the success of Galli Spa, the latter able to meet the pressing demand for technological innovations, while falling into step with the time schedules and with the methods set by the fashion industry.

Thanks to analysis laboratory and to specialized technicians, the enterprise, with the support of the clientele, devises and supplies cutting-edge solutions and processing operations. Worth mentioning also simulations run in a Demo area, where it is possible to produce samples by relying on the most advanced technological innovations launched on the market. www.gallispa.com