The Lederpol line of LEDER CHIMICA is the new range of softening polymers, that come from acrylic polymer and softening agent chemical reaction, combined with other elements. These polymers feature extremely high performance and light-fastness; moreover, they successfully passed several tests, such as the ageing test, tropical test, odor test, and meet the strictest requirements in terms of fogging and VOC. The Lederpol line is divided in fat liquor and auxiliaries with softening properties.

Depending of the type of the polymer, it can be used with different purposes: for example, if combined with other fat liquors it can increase the performance ensuring a better distribution, penetration and fixation on leather, giving excellent results in terms of low COD. Replacing the fat liquors partially or totally with a mix of Lederpol during the retanning process, allows to save from 20% to 30% of the normal retanning products used in a standard cycle, maintaining the same features: the final leather boasts the same fullness and softness.

If the fat liquors are substituted completely with the polymers in a cycle article, to increase the milling time compared to a normal process is strongly recommended.

In order to properly understand the properties and to set up the right mix, several adjustments and tests must be done; our technical staff is available to assist any customer during this process.

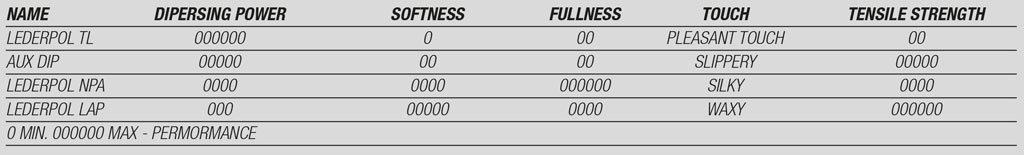

Some polymers are able to better/improve the tensile strength; others are instead useful for waterproof items. , the properties of each polymer: